Apple is opening up its world of iPhone recycling

An Earth Day reminder: All those iPhones don't recycle themselves.

Hidden not far from downtown Austin, Texas, a research lab is working to change the way we recycle electronics. And it's being run by Apple .

If you don't know exactly where it is, you'll definitely miss it.

There are no signs. The parking lot is almost empty. There's an unremarkable door at the bottom of a set of generic cement stairs. It looks like the back entrance to a rundown mall.

But inside is a 9,000-square-foot warehouse where, just a stone's throw from the front door, you'll find one of the most interesting robots in the world.

Daisy is actually a series of five robot arms working in an elaborate dance.

Meet Daisy. Daisy is 33 feet long, has five arms and can methodically deconstruct any of 15 iPhone models -- from 2012's iPhone 5 to 2018's iPhone XS -- at a rate of 200 per hour. In a coordinated and sometimes violent dance, Daisy removes the screen, battery, screws, sensors, logic board and wireless charging coil, leaving its husk of an aluminum shell.

Apple invited me here not just to see Daisy in action, but also the Material Recovery Lab that's been built up around it. Last year, in time for Earth Day then, Apple announced Daisy for the first time to the world via a press release and video. Now it's inviting in academics, recyclers and other companies to learn how Daisy works.

And, hopefully, use its technology to make e-recycling around the world better.

"This is about the big, hairy goal of making all our products from recycled materials," said Lisa Jackson, Apple's vice president of environment, policy and social initiatives, in an interview. "It's going to take a while, but it'll also take tons of innovation."

Apple thinks sharing what it's learned could help others, too.

And as it happens, we could use all the help we can get. A United Nations report found that in 2016, the world created 44.7 million metric tons of e-waste, or 2.1 million Statues of Liberty stacked together. And just 20% of that, or 8.9 million metric tons, was recycled.

Daisy can disassemble 15 iPhone models at a rate of 200 per hour.

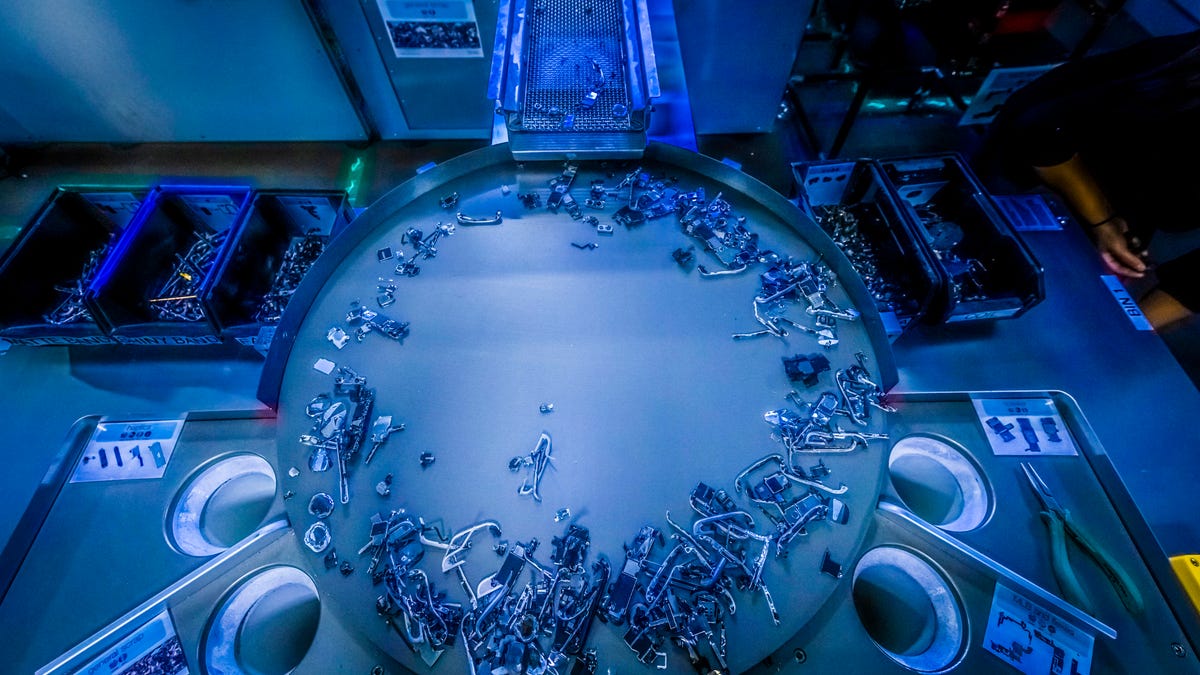

When other electronics like laptops, printers and monitors are recycled, they don't go through a Daisy. They're put in a shredder or a hammerlike pounder that breaks apart the devices in an effort to expose the elements inside. This process often mixes materials together, making them impure and less valuable. Still, a series of sifters and magnets attempt to collect the recyclable materials before the rest is thrown out.

That's right: Recycling produces trash too.

This is where Apple thinks it can help. If recyclers can learn how to more easily take apart technology, they can more efficiently collect the valuable materials. Give a recycler a bunch of copper charging coils, and it's better than asking it to break apart a phone in search of them.

Apple thinks this can be done in part because it's starting to get there itself.

Apple is one of the world's top phone makers, shipping an estimated 218 million iPhones last year alone. Sometime this year it may pass 1.5 billion iPhones since the first one debuted, meaning in a little over a decade, Apple's shipped enough phones to circle the planet more than 13 times.

That's great for Apple's bottom line, and helped to turn the Cupertino company from a niche computer maker into one of the world's most highly valued companies -- ever. But it's not so great for an employee's conscience.

Apple's mammoth success -- and the business of countless other computer and gadget makers -- has come at a high cost, counted in untold tons of aluminum, cobalt, copper, glass, gold, lithium, paper, plastic, steel, tantalum, tin, tungsten, zinc and many other raw materials that are smelted, extruded, compressed, etched and polished into the magical device you're using to read this story.

"You have a perfect storm brewing of everyone needs this stuff and the supply is rapidly shrinking," said Callie Babbitt, an associate professor of sustainability at Rochester Institute of Technology. Some materials could be used up in the next half century, she said, leaving us without key components for the screens on our TVs and tablets, or pieces that help magnets make the alert vibrations on our watches and phones.

Liam, Daisy's predecessor, was designed for the iPhone 6.

Another problem comes when we upgrade to new devices, something the tech industry encourages through warranty expirations and payment contracts. Our old ones often go in a drawer as a backup "just in case" phone. Or we may ship them off to an e-recycler that shreds or smashes them to collect the materials as efficiently as possible. Worse, we might just toss our once-loved phone into a landfill.

You could see Daisy as Apple's attempt to right some of these wrongs. But if you squint and look another way, Daisy might look like an expensive and cynical PR ploy by one of the world's richest companies to whitewash the damage it's doing to the planet through its massive size.

"I call her Daisy the Deathbot," said Kyle Wiens.

Wiens is a tech repair advocate and head of online instruction site iFixit. He's spent his career doggedly challenging Apple and other tech companies to make their devices easier to repair.

He's also spoken to legislators around the country to encourage "right to repair" laws, forcing companies to allow people access to tools and information to service their devices. And in 2016, he sold $21 million worth of toolkits and parts to help people swap out bad screens, cameras, buttons and batteries on their devices.

I asked Wiens what it would take to convince him that Apple is serious about all this green stuff. What would it take for Apple to live up to its feel-good advertising, like when it publishes "environmental status" reports touting how its devices are free of certain chemicals? And when would it be meaningful that Apple's latest MacBook Air chassis are made of 100% recycled aluminum, including some from iPhones?

One challenge is Apple's secretive culture, he said. The company holds so many things close to the vest, from its plans for the next iPhones to the repair manuals to fix them to the technology behind Daisy. That makes it hard for us to determine what's real and what's just marketing.

What if Apple did the next best thing and let companies come in, see how Daisy works and try to retrofit some of that technology to existing recycling programs?

"That would be interesting," Wiens said.

The iPhone afterlife

Apple built Daisy to help with what's known as end-of-life iPhones. It would cost too much to refurbish these devices back to perfect working order, so Daisy guts them instead, stripping out their parts to be recycled into raw copper, aluminum, cobalt and other materials so they can be used anew.

All told, of the roughly 9 million iPhones Apple received back from customers last year, 7.8 million were refurbished and sent to new users, while 1.2 million were sent to Daisy.

Apple understands not everyone has near-infinite money and resources like it does. The iPhone maker notched nearly $20 billion in profit during the holiday season last year, and it has more than $245 billion in cash and investments to draw from. That helps pay for the significant cost behind building expensive machines like Daisy.

Apple purchased some of the machines e-cyclers use today. It hopes Daisy's technology can help to improve them.

To point other companies in the right direction, Apple's purchased large shredders and pounding machines you find at most e-recyclers around the world. It's also set up tables alongside them so that the people who come into its lab can work with Apple to retrofit technology like Daisy's innovations onto the existing technology most recyclers already have.

Apple plans to patent and license Daisy's technology too.

"Technology by definition is all about the new, about things that couldn't happen before but now it can because of some remarkable innovation," Apple VP Jackson said.

Jackson joined Apple in 2013 after a long career in government, working as the commissioner of environmental protection in New Jersey, the chief of staff to the governor of New Jersey and ultimately, for President Barack Obama, as the first African American to lead the Environmental Protection Agency.

Lisa Jackson heads up Apple's environmental initiatives.

At Apple, Jackson has risen to become its top policy person, overseeing social initiatives, governmental affairs and environmental work, like Daisy.

During a panel session a couple years ago, she said Apple's focused its efforts on durability, with the understanding that its products will often have two or three owners before they might get recycled. "We're committed to a circular economy approach to manufacturing," she said then, underscoring how the company wants to encourage people not to hold onto devices or toss them in drawers, but to give them back to Apple so they don't end up wasted or in landfills.

"There's 100-plus elements in an iPhone, and we're looking at how to move them back through the chain," she added. "The business opportunity is to come to Apple and say 'Hey, I have a process for getting cobalt out of batteries,' or 'I have a process for getting tungsten.'" Then, Apple will pay for it.

Ultimately, Apple said, it wants to create a "closed loop" of recycling. At Apple, that means taking in devices and either refurbishing them to good-as-new and sending them off, or recycling them so the materials can be used again in new devices.

So far, it's begun sending the iPhone batteries Daisy pulls out to a recycler who uses the cobalt to make new batteries for Apple products. The company also uses 100% recycled tin in the solder on the logic boards of 11 products. And don't forget those 100% recycled aluminum MacBook Air housings.

Apple isn't the only one with a robust environmental program, but it's on a short list. Not far from Apple, Round Rock-based computer maker Dell , the third biggest PC maker, has been using recycled ocean plastics in its packaging. It's also been pushing sustainability, waste-free shipping packages and refurbishment.

Typically a phone with a cracked screen can be refurbished and sent back into the wild.

HP, the second biggest PC maker, said that its paper and packaging no longer come from deforestation, that some of its products are made with recycled plastics and that it offers some of the most easily repairable computers in the industry.

Lenovo , the world's largest computer maker, says it's been increasing its use of recycled plastics in the devices it sells.

And Samsung , the world's largest phone maker, says it's recovered 28.3 million metric tons of its products, including TVs and refrigerators , to be refurbished or e-cycled. It's also pledged to create a "closed loop" recycling program, similar to Apple's efforts.

But experts say all the tech giants have a ways to go before they undo the waste their customers put into the world.

"The companies are experts at creating products, but not experts at reverse logistics, bringing their products back to the smelters of the world," said Mathy Stanislaus, a fellow at the World Resources Institute.

Daisy is actually Apple's second-gen recycling robot. The first was called Liam. Announced in 2016, it was designed to work with the iPhone 6 .

Apple chose to focus on the iPhone because it's among the toughest products to recycle and because it sold a bunch of them. Eventually, Jackson said, the lab will work on iPads , Macs and even AirPods too.

Materials pulled from typical e-cycling, seen here, are often left co-mingled and impure.

Getting there

Whether Apple will attract academics, recyclers and other companies to participate in its new program is an open question.

In the meantime, it's also working to collect more unused or destroyed iPhones to either refurbish or send them to Daisy. The company said US customers can now return iPhones to Best Buy stores too.

It's also expanded its iPhone Upgrade Program, a monthly installment plan people can use to pay for their iPhones. When new devices come out, they can merely turn in their old iPhone and get a new one, restarting the clock with a new installment plan. As you probably guessed, those phones either get refurbished or sent to Daisy.

A next step could be for Apple to fully lease phones to us, said Jim Puckett, executive director of the electronics waste watchdog group Basel Action Network. That would help to cut down on waste, as we'd give the phone back to Apple with each new upgrade.

"Apple's the brand to do it, because their demographic cares about the environment," he said.

At the end of my visit to Apple's facility, I took a moment amid the cacophony of Daisy's servos and punches pushing screws out of the iPhones to look around at Apple's otherwise sparse facility.

While people may not agree on Apple's motivations, or its methods, no one disagrees about the problem. It's no surprise that Apple's hired into its ranks former Obama-era government workers who are passionate about climate change, its effects on the planet and the role companies like Apple play.

The question is whether Liam, Daisy and Apple can truly make a difference. I hope they do.

Originally published April 18 at 5 a.m. PT.