How Bentley handcrafts its luxury cars (pictures)

CNET takes a look inside luxury car manufacturer Bentley's factory, to see how it relies on handcrafting rather than robotics to create its opulent vehicles.

This is the Bentley Mulsanne, Bentley's flagship luxury vehicle, full of all the hand-crafted wood and hand-stitched leather you'd expect on a top-end car with a price tag clocking in at over £200,000 ($335,000 or AU$600,000).

It takes 400 hours to produce just one Mulsanne from start to finish, a process that includes hand-building the W12 engine, over 5,800 spot welds in the body work -- mostly done by hand -- and 150 hours of hand-stitching the leather interior.

I managed to get inside this facility, in Crewe in northern England, to see first-hand how Bentley produces the Mulsanne, as well as the sporty Continental. Click through to see this luxury vehicle go from a bare skeleton to an opulent lounge on wheels.

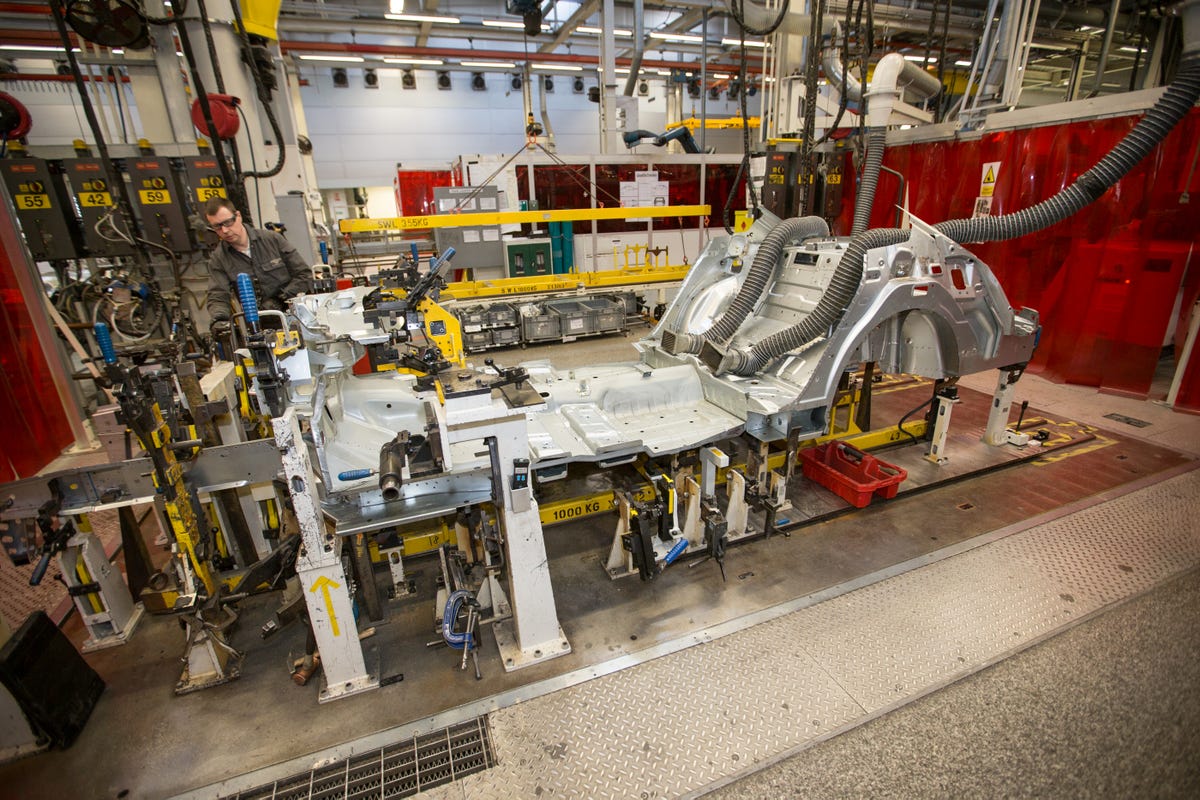

The cars start out in this rather unassuming skeletal form. It's in the Body in White facility where all the welding for Bentley's cars are performed.

Over 5,800 spot welds are performed in order to securely bolt the car together.

More than 3,700 employees work in the factory, most of whom are from the local area. Many of the employees I spoke to have direct relatives who work or have worked in the Crewe factory.

More than 75 percent of those welds are done by hand.

You can see the stages involved in welding together the large body panels. It begins as a rough weld and is then worked, in order to make it totally invisible under the paintwork.

The welding line is filed by hand...

...and then hit from within with a mallet to ensure any bumps are forced outwards in order to be filed off.

The resulting line blends seamlessly with the surrounding metal. It's impossible to tell by touch alone that it's not one single piece.

Any imperfections in the body work are sanded down.

It's rigorously checked up close to ensure that no marks remain.

These huge banks of light help the inspectors find even tiny imperfections in the metal. If the panels don't meet standards, they are sent round the sanding process again.

Gaps between doors are measured by hand to ensure they meet specifications.

The gaps are worked by hand with a file if the numbers aren't exactly as they should be.

Meanwhile, the interior aspects of the car are produced. This is where the steering wheel is wrapped in leather and stitched by hand.

The steering wheel of the Mulsanne takes one person five hours to produce and includes 620 individual stitches from 10 feet of thread.

Scissors and a fork may seem like the most low-tech tools you could expect to find in a luxury car factory, but they're tried and tested items that for years have allowed workers to achieve the quality required in Bentley's leather components. If it still works, why change it?

And here's the finished wheel. Lovely stuff.

There's a wide selection of threads to hand to produce contrasting colours on the wheel and seat stitching.

Here's the range of leather hides, ready to be crafted into the interior seats. The hides are from bulls only, reared in Scandinavia and Germany on farms that don't use barbed wire fences -- to ensure the bulls don't damage their hides.

The hides are thoroughly checked and any imperfections that can't be used in the car are clearly marked.

It takes a whopping 14 bull hides to fully deck out the flagship Mulsanne. The Continental meanwhile takes nine hides.

Once the hides have been selected and properly checked over for any imperfections, a laser cutter is used to accurately shape the hides.

As with the steering wheel, all of the internal leather work is stitched by hand.

It takes roughly 150 hours to stitch the interior trim on the Mulsanne. That's a lot of needlework.

Smaller pieces of leather not used in the seats aren't thrown away -- they're used for smaller parts of the car such as on the doors, dashboard or gear knob.

And now we come to the wood shop, where all of the interior wooden panelling of Bentley's cars is produced.

In the image shown here, you can see how the panels begin life in the factory as large blocks, before being gradually cut down in size, lacquered and then polished.

Here, a belt sander and a keen eye for detail is used to create a smooth finish on the wood.

Various woods are available to use in the interior. The interior panels on each car are all cut from the same tree to ensure consistent wood grain pattern, colours and to ensure that the wood ages in a uniform way.

The wood is stored in this temperature and humidity controlled room.

Bentley's wood specialists check the quality of around 25,000 square metres of veneer in its raw form during selection.

24 leaves of veneer wood get squashed into each panel.

Here's the wood closer to its raw state.

The panels go through multiple stages of polishing -- all done by hand, of course.

Back to the car itself now. Here's the Mulsanne's gigantic W12 engine. Bentley's Crewe factory is actually the world's largest producer of the W12 engine.

The factory produces the engine from scratch, starting from this rather unassuming block. It takes 30 engineers over 12 hours to build one engine.

It's starting to come together, but the engine is a long way before it's ready to run.

I have no idea what this chap is up to with that screwdriver, but I trust he knows what he's doing.

The inside workings of a Bentley W12 engine. Complex.

Every engine comes with a plaque engraved by the lead engineer who built it. You'd be proud too, if you'd built one of those beasts.

The plant isn't completely devoid of robots -- this little guy navigates using the black lines on the floor, taking heavy components where they're needed.

The body of the car is coming together. This part of the process is where many of the external components like the bonnet and boot lid are put in place.

The wires for all the electronic components are threaded through the car here. Of course you'll find items like satellite navigation on board, but you'll also need electronics for the champagne fridge built into the back seats, the personal Wi-Fi hotspots and the iPad tables built into the driver and passenger seats.

The whole centre console is made in advance so it can be simply slotted into place.

Robots do have some jobs in the factory -- for example, crimping metal edges is performed more efficiently and more accurately by robot hands than human ones.

Some customers will choose to visit the factory to select custom options for their car. While there, they can get a taste of some of Bentley's history, including a look at this 1929 Blower Bentley.

Although you probably wouldn't expect a standard home iron to be used in car production, Bentley says it's the best tool for the job.

Would you fancy this split tone design on your own car?

Surprise! It's not a car at all, but a full scale model, carved out of clay by hand. These models are used in the later stages of product development to not only show how the finished car will look, but to allow it to be tested in wind tunnels and refined.

It takes six weeks to create this clay model of the Continental.

The whole process of creating the Continental, from early design sketches, through development and finally into production took over three years.

Here are some of the old tools used in creating Bentleys of the past.

The car bodies are secured in place under these arms in order for lasers to accurately measure the car, ensuring that no panels are too big or too small.

These plates are put in place over the car to act as guides for some of the welding points.

Part of the factory is home to a vast storage facility that contains the body panels of all the cars, ready to be put into place.

The panels are all formed off-site. The aluminium parts are heat-formed at temperatures exceeding 500 degrees celsius.

Here's one of the Continental's seats being produced. The odd-looking bags being hung in the back rest are actually for the massage feature.

The various leather and colour options of the seats, stitched by hand earlier, ready to be fitted.

The factory was first opened in 1938, although it wasn't until 1946 that the first car with the Bentley name on it rolled off the line.

Bentley does all its training in-house. This training station teaches new recruits the fine detail required for stitching the leather interiors.

All aspects of the cars are checked at every stage of production. Three cars are also selected every week and checked by an independent auditor.

And here's the finished model, ready to be driven home. Carefully.