Plugging into new lighting technologies (photos)

At its research labs, General Electric is investing in new energy efficient lighting technologies to improve LED performance and, someday, print sheets of OLEDs.

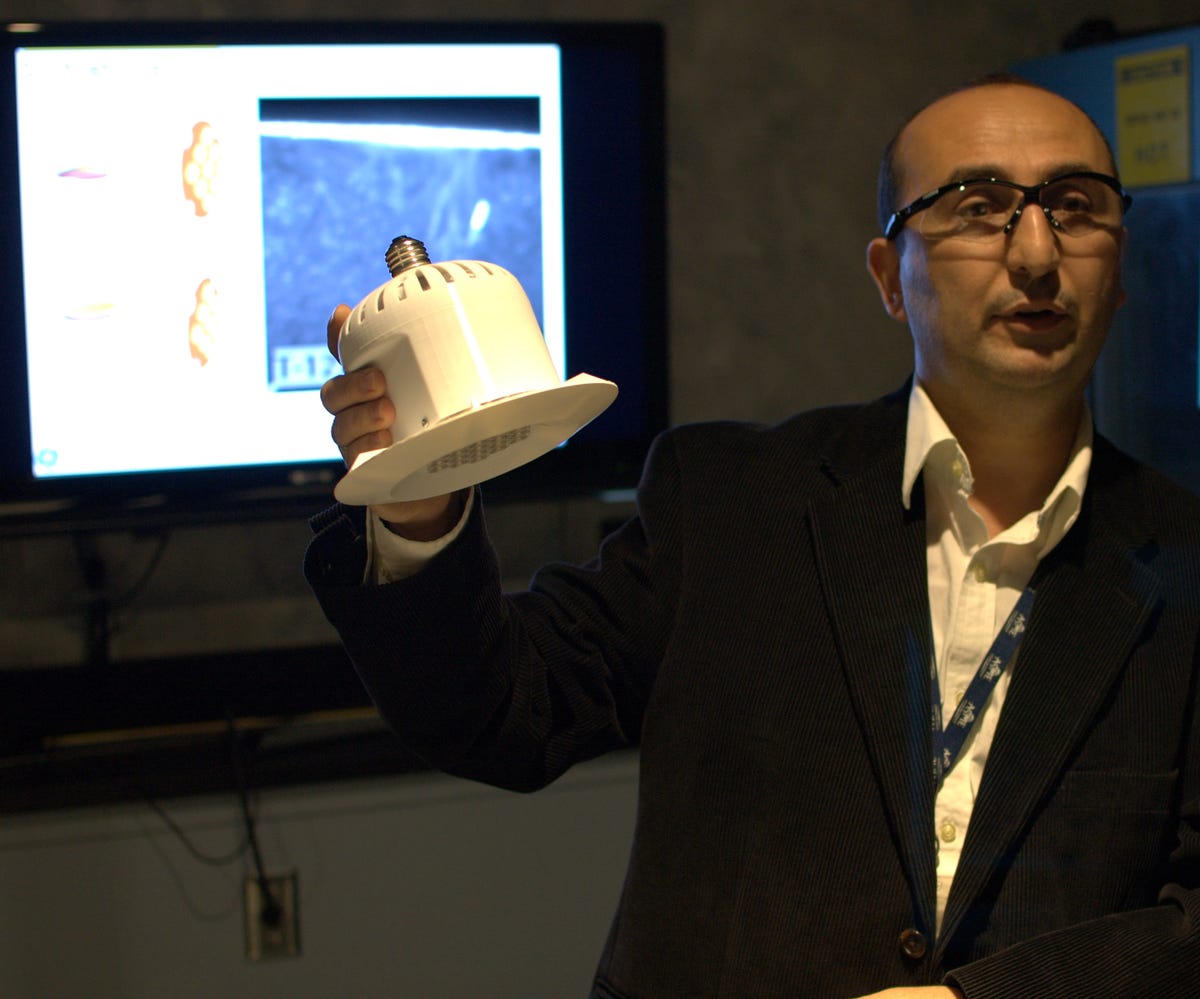

Prototype LED

NISKAYUNA, N.Y.--General Electric yesterday held a symposium on lighting at its Global Research center here, where it introduced a prototype of a very bright LED, shown here. The LED downlight uses an active cooling system that allows it to put out 1,500 lumens. That's the same as a 100-watt halogen, but it uses one-third of the energy. The active cooling system means that this light takes up about half the space as a 600-lumen downlight.

See related story: LEDs ascending but still face stiff competition.

Dual cool jets

The cooling technology used in this LED bulb comes from GE's work on fluid dynamics for jet engines. GE researcher Mehmet Arik shows how synthetic jets pull in hot air at a certain speed but eject the heat more quickly. The net effect is a more effective heat sink than natural convection, which is important to maintaining the long life promised by LEDs.

Active cooling lighting

The quarter-size device next to this downlight is the active cooling system integrated into the luminaire. Hot air is pulled into the device, which inflates like a bellows then ejects the hot air. It requires electricity to run, but it's not expensive to make and will allow GE to use fewer LEDs for a given light fixture.

OLEDs in hand

GE lighting researcher Anil Duggal shows off organic light-emitting diodes being developed at GE's Global Research Center. While LEDs offer a single source of directed light, OLEDs are a distributed source of light and can be used on thin, flexible substrates. Duggal expects that OLEDs won't be commercial products for another five years.

Sheets of OLEDs

One of the primary benefits of OLED lighting is that it can be printed quickly on flexible materials. Here, Anil Duggal shows a roll of OLEDs put onto sheets of plastic embedded with a transparent electrode. GE is seeking to optimize the manufacturing process for OLED lighting and find good applications for it.

Flexible OLED

One of the areas where GE thinks OLED lighting can be used is with flexible retail displays, such as curved walls. In terms of efficiency, GE has managed to get 56 lumens per watt with OLEDs, which approaches the efficiency of compact fluorescent bulbs. Another big technical challenge is improving the lifetime of OLEDs, which degrade when exposed to oxygen and water.

Phosphors

GE's lighting research has a group dedicated to developing phosphors, the materials used to modify light so that it's appealing to people. The phosphors in these vials show how different materials produce different-color light. In a fluorescent bulb, for example, phosphors to make red, blue, and green light are combined to create a white light. To the left of the vials is an LED chip, which also requires phosphors to modify the light.

LED blue light

LEDs give off a blue light like, this which feels cold compared to the warm glow of halogens or incandescent bulbs. The blue light here is coming from an LED chip. The yellow cap next to it is coated with phosphors to adjust the light quality and temperature.

GE LED bulb

Here is GE's LED bulb coming out later this year, which is designed as a replacement for the 40-watt incandescent bulb. The fins along the side are heat sinks to wick away heat, which degrades the lifetime and, over time, the light quality of LEDs.

LED comparison

Established lighting companies, including GE and Philips, are touting the quality of their LED bulbs. One of the challenges with LEDs for general lighting is that they direct light, so using an LED for a desk lamp doesn't always make sense. GE's bulb, shown on the left, is designed to disperse light in all directions.

Long history of incandescent bulbs

The Schenectady Museum and Planetarium displayed a number of old bulbs at GE's lighting symposium yesterday, including these. The bulbs were made from the late 1880s to the early 1900s. On the right in front is a 96-year-old replica of Thomas Edison's first commercial bulb from the 1880s. The fourth bulb from the right in the back row is a gas-filled bulb from 1915, which was inexpensive enough to make electric lighting available to the general public, according to a representative from the museum.

Arc light

Here is one lighting technology that didn't make it very far into the 20th century. It's an arc light from the late 1880s used as a street light as an alternative to gas lamps. It worked by sending electric current across a gap between two pieces of carbon, which gave off a glow as the carbon burned. Incandescent lighting ultimately won out over arc lamps.

GE held its lighting symposium on October 21 to commemorate the day in 1879 when Thomas Edison was able to run an incandescent lightbulb for several hours, a technical breakthrough at the time.