Photos: How Ford 'life-proofs' its cars

Beyond physics and number crunching, engineers throw a little fun into the mix.

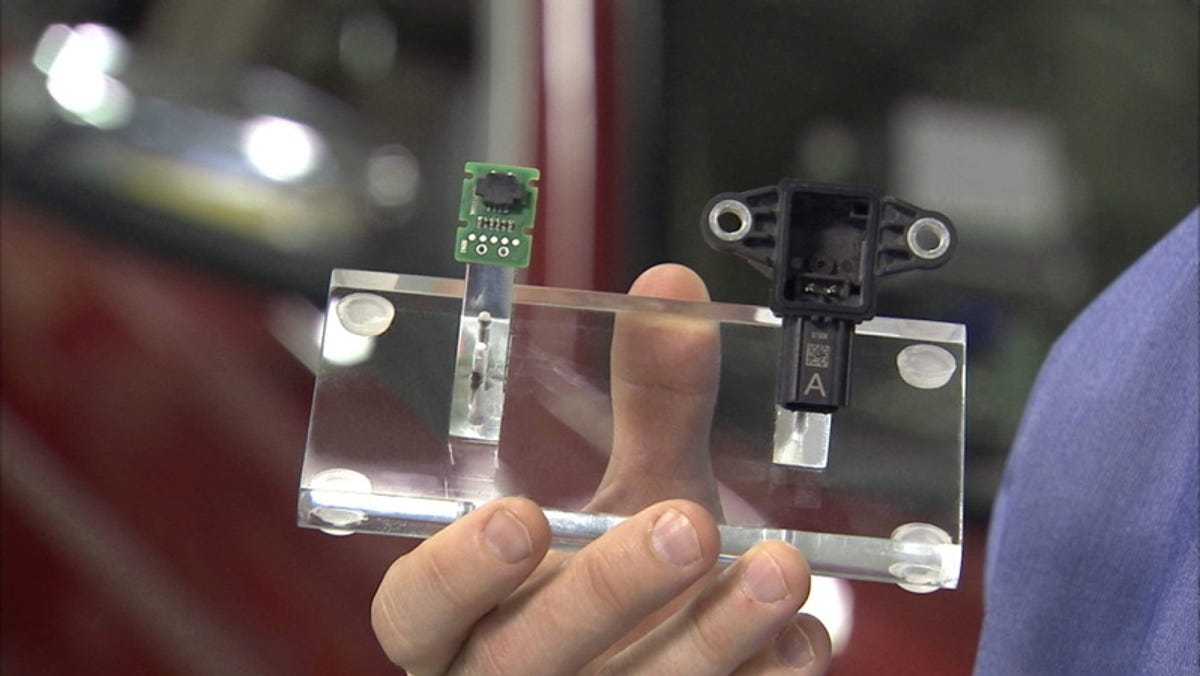

Ford air bag sensor

Ford Motor on Tuesday lifted the curtain on one of its testing labs, presumably in an effort to promote new safety features in its upcoming line-up of cars.

Here's a glimpse into the world of crash test dummies. (Or is that smarties?)

Ford's new air bags use pressure-based sensors, shown here, that enable them to deploy 30 percent faster than traditional systems that use accelerator-based sensors, according to Ford.

Ford bike wheel

Ford thrown ball

A robot replicates the impact of a hard-thrown ball into the side of a car. Ford engineers test and adjust the pressure-based sensors for its new air bag system to see that the air bags don't deploy from everyday abuse.

Ford water cannon

In December 2008, Ford began to use water cannons with compressed air charged to 130 psi to test how a car reacts to being struck, and how well its stability control kicks in when this happens.

Ford water cannon splash

When the water cannon shoots a blast of water from the car, the recoil causes the car to skid. Ford engineers have used this method to test a car's stability control on slick, wet, and dry roads.

The company boasts that the method saves money, since engineers don't have to repeatedly crash cars.

Ford MKS ballon test

Ford uses giant car-shaped balloons to test out its adaptive cruise control and collision warning/braking features, which will be implemented on the 2010 Taurus and Lincoln MKS.

Ford rough road

A test track of curbs, potholes, and other road imperfections enables test drivers to determine how air bag sensors hold up next to extreme jarring and jostling.