To make sure it never goes through another battery debacle, Samsung implemented a new eight-point safety check to test batteries before they're put in phones and shipped to buyers.

In Gumi, South Korea, is one of Samsung's nine factories for building phones and tablets.

During a visit to Samsung's Smart City campus in Gumi, CNET reporter Shara Tibken was given a tour of most of these new testing processes.

"The emphasis is to make sure the batteries don't have any problem," says Daniel Lee, director of global manufacturing and innovation.

The new safety check includes more frequent battery testing as well as overcharging tests, nail puncture tests and extreme temperature stress testing.

The number of devices and batteries tested with Samsung's new process varies from test to test. For some, every device will be tested. For others, it will be just a sample.

In examining last year's Note 7 fiasco, Samsung realized none of its previous tests would have caught the phones' battery problems.

So it changed the process, instituting an eight-point inspection that includes some steps that are new and others its suppliers had conducted.

The TVOC (Total Volatile Organic Compound) testing ensures there isn't any possibility of leakage of the volatile organic compound.

Breaking down a battery to take a look at every component is now part of Samsung's battery safety process.

Samsung technicians disassemble the battery to assess its overall quality, including the battery tab welding and conditions of insulation tape.

Samsung can run as many as 60,000 phones at a time through its charge-and-discharge test, one of three new tests the company has added to its safety check.

Intensive tests simulate accelerated consumer usage, pushing the batteries to their limits under extreme real-world use scenarios.

Batteries undergo a large-scale charge and discharge testing process at the Gumi, South Korea, facility.

Battery life cycle charge testing is part of Samsung's eight-point battery safety check.

More accelerated usage testing.

In addition to hardware battery tests, the rigorous process looks at the role software algorithms play as well.

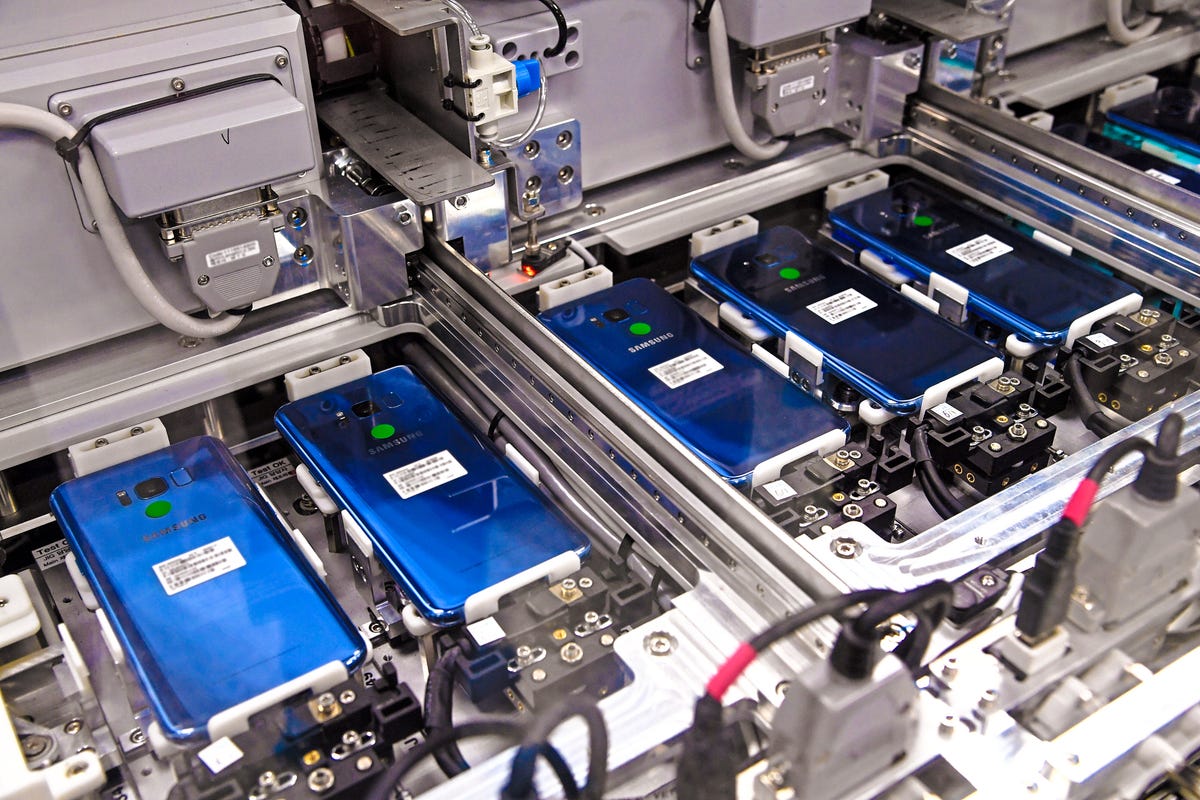

Samsung uses automated equipment at its factories to help speed up the assembly and manufacturing process.

OCV testing, seen here, checks for any change in voltage throughout the manufacturing process from component level to complete device.

Nine Samsung factories around the world assemble Samsung phones in the newly updated manufacturing and testing environment. It takes about 13 minutes for a typical worker to assemble one phone.