HP Labs trades glass for plastic displays (photos)

HP is testing ways to use plastic displays for solar panels, e-readers, and possibly future flexible displays.

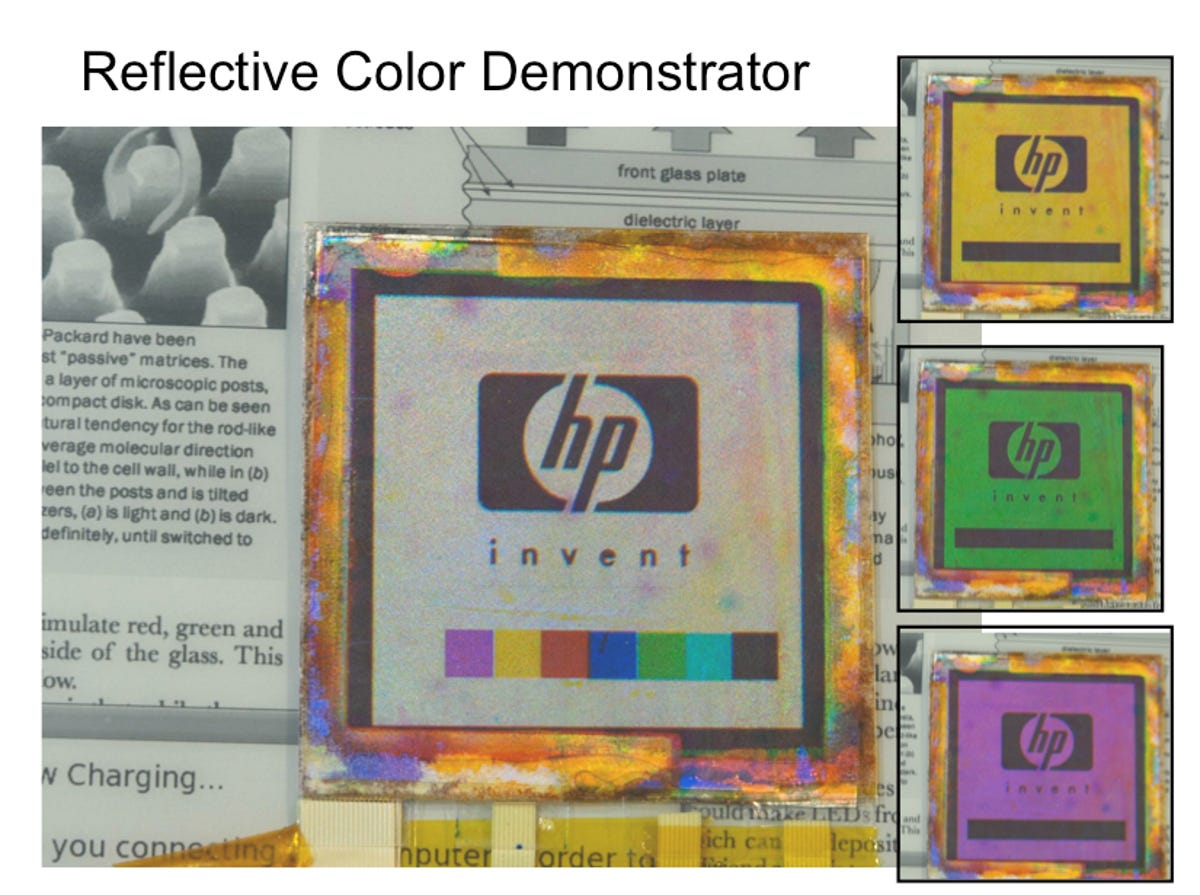

Color e-ink on plastic

The reason the Kindle and other electronic-ink displays use black and white is that without a light source, rich colors are hard to produce. Here is an example of HP Labs' "roll-to-roll" plastic display manufacture technology using color electronic ink. HP Labs uses three different layers of colors to produce as bright colors as possible.

Future applications include wrap-around displays for gaming and retail store signage.

"In 10 years glass will be as much a memory of displays as cathode ray tubes are today," said Carl Taussig, the head of HP Labs' Information Surfaces Lab, during a tour Friday.

Testing equipment

Plastic display

Plastic solar cells

One example of an actual product using this technology: the flexible wrist display currently being made for U.S. troops. Using flexible solar cells for charging the display worn on the wrist, it uses e-ink to show each wearer relevant information.

A company called Phicot, which was spun off from HP Labs, is producing the wrist displays. The first prototypes will be available in 2011.