Designing a Harley-Davidson engine (photos)

The Harley-Davidson Steel Toe Tour at the company's Powertrain Operations plant in Wisconsin gives visitors a behind-the-scenes look at the engine-build process, as well as how a bike evolves from an idea to reality.

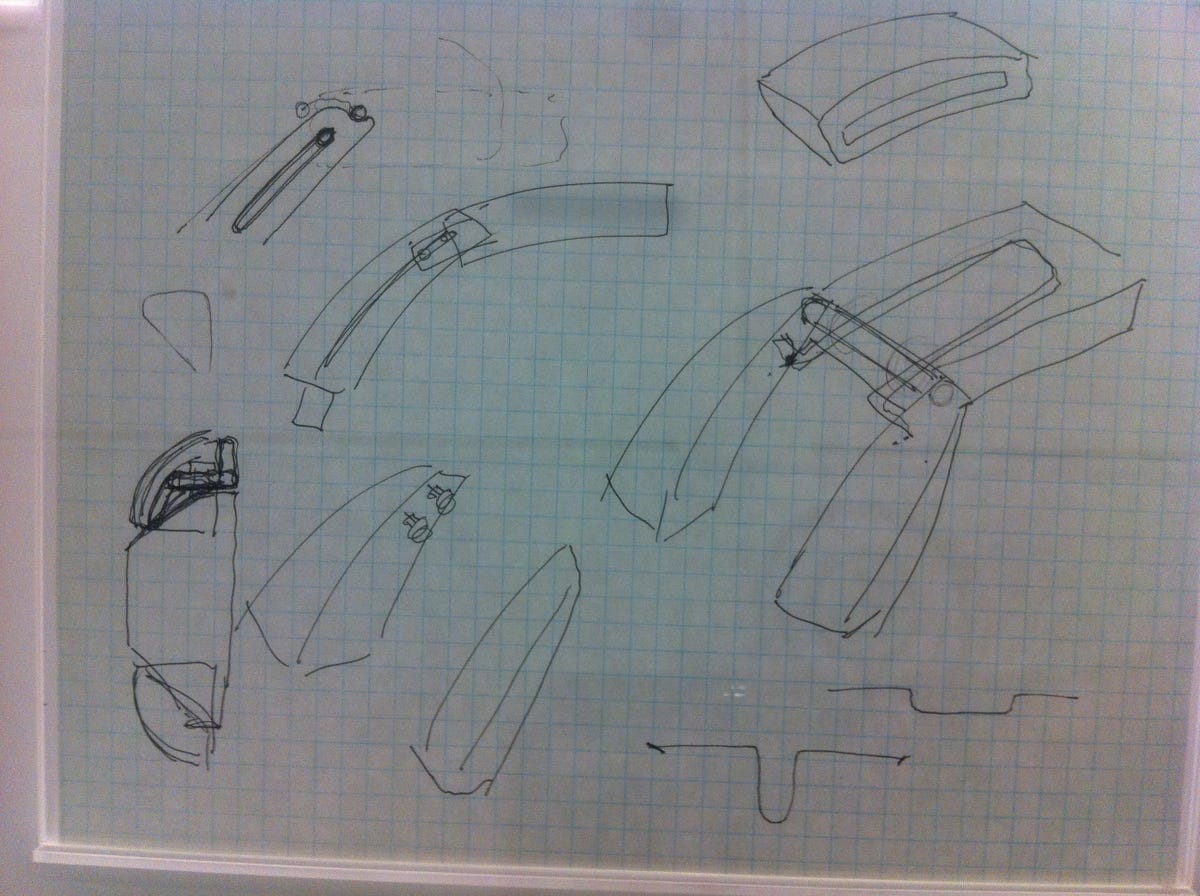

Sketch of a Harley-Davidson concept component

MENOMONEE FALLS, Wisc.--The Harley-Davidson Steel Toe Tour at the company's Powertrain Operations plant here gives visitors a behind-the-scenes look at the engine-build process, as well as some insight into how a bike evolves from a sketch on a notepad to a roaring machine on the open road.

In 2010, Harley-Davidson, the last American motorcycle manufacturer, started giving tours at the company's primary engine manufacturing plant here just north of Milwaukee. Only about 2,000 motorcycle enthusiasts have taken the Harley-Davidson Steel Toe Tour, and CNET got to tag along for it this weekend.

While portions of Harley-Davidson's operation are off limits to photographers, we were allowed to offer some images from the company's factory and museum archives. This rare sketch of possible passenger seat designs for the Harley-Davidson Rocker concept bike shows that the entire process all starts with pen, ink, and paper.

Harley-Davidson V-Twin blueprints

Harley Davidson V-Twin schematics

Harley-Davidson test parts

Harley-Davidson V-Rod clay mockup

The Harley-Davidson XR1200 styling mockup