Intel buys the industry's first next-gen chipmaking tool to try to reclaim lead

The chipmaker is trying to return to the forefront of the processor manufacturing business after losing its lead to Samsung and TSMC.

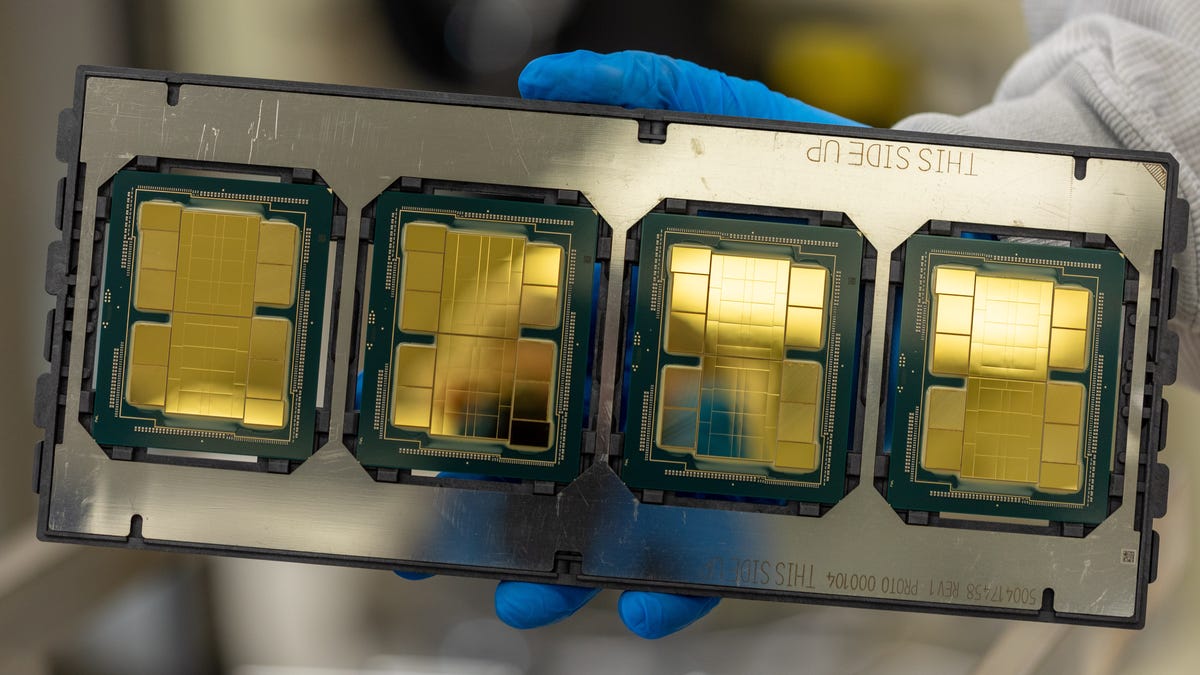

A quartet of Intel Ponte Vecchio processors

As part of Intel's effort to reclaim processor manufacturing leadership by 2025, the company has ordered the first of a new generation of chipmaking machines from Dutch specialist ASML, the companies said Wednesday. The device, called the Twinscan EXE:5200, is scheduled to be delivered in 2024 for operations beginning in 2025.

Such machines, each costing a budget-busting $340 million on average, according to ASML forecasts, are critical to advancing processor progress. Miniaturizing chips is getting steadily harder, but doing so is crucial for tech giants reliant on progress in smartphones, PCs and data centers.

Intel for decades led the chip manufacturing industry, steadily shrinking chip circuitry so processors could tackle more and more work. Even as other players like GlobalFonudries and IBM fell by the wayside, choosing not to stay on the leading edge, Intel manufacturing problems meant it ceded its lead to Taiwan Semiconductor Manufacturing Co. (TSMC) and Samsung.

A core challenge to chip miniaturization is inscribing ever smaller circuitry onto silicon wafers. ASML builds the machines that handle the primary part of this process, called photolithography, which literally means "writing on stone with light." For this process, Samsung and TSMC have both made the transition to extreme ultraviolet (EUV) light, which has a shorter wavelength and therefore can inscribe finer patterns that, over many steps, become a processor's transistors and wires.

Intel was late to adopting EUV lithography, but with an engineer in charge again, Chief Executive Pat Gelsinger, is keen accelerating progress. He's said Intel would be the first to order a more advanced EUV tool whose topics use a high numeric aperture (high NA) to inscribe even finer features. ASML said Tuesday it received its first order, and Intel on Wednesday said it was the buyer.

Intel declined to comment on the tool's price.

Being first in line doesn't guarantee success. With so many aspects to chipmaking, it takes years to bring a new manufacturing process to volume production, and Intel is late learning about first-gen EUV. Intel expects to start selling its first EUV chips this year and its first high NA EUV chips in 2025.

Processor makers are investing gargantuan sums of money into new chip fabrication facilities, called fabs, prompted by a global chip shortage and the spread of processors into every corner of our lives. Intel plans "megafab" sites in the US and Europe, each costing about $100 billion, and TSMC announced it's spending $40 billion to $44 billion this year on new fabs.

Intel has a series of manufacturing processes planned in coming years. The current one, Intel 7, is used to build new Alder Lake processors. Intel 4 is due to arrive in chips in early 2023, introducing EUV lithography to Intel products, followed by Intel 3 in late 2023. Next comes Intel 20A in 2024 then Intel 18A, with high NA EUV, in 2025.