'BusinessWeek' ponders lithium ion market war

"Should Uncle Sam provide billions in loans and grants to a promising but unproven business?" This is one green-tech question the magazine poses.

"Should Uncle Sam provide billions in loans and grants to a promising but unproven business? Or should the government wait for the market to sort things out before it backs a U.S. company?"

Those are questions posed in a BusinessWeek article last week. However, the questions are largely rhetorical: the U.S. Department of Energy already has a $25 billion Advanced Technology Vehicles Manufacturing Loan Program, and many car and battery companies are counting on these loans to aid their development and production of lithium ion batteries.

So it's not a question of "should," it's a question of "how?"

Lithium ion batteries will add at least $8,000 to the price of a production plug-in hybrid vehicle, according to BusinessWeek. However, that amount is probably on the low side when you consider that the Chevy Volt is predicted to cost a bit less than $40,000, a good portion of that price being the battery. Another manufacturer representative estimated that a lithium ion battery currently costs approximately $22,000, effectively putting the electric car out of reach to all but the well-heeled greenies.

Despite the disproportionately high vehicle price, the tax break for buyers of the Chevy Volt is only $7,500. Which isn't as generous as the $9,000 tax break the Japanese government will grant buyers of the cutesy electric iMiev when it goes on sale in Japan this year, according to AutoBlogGreen.

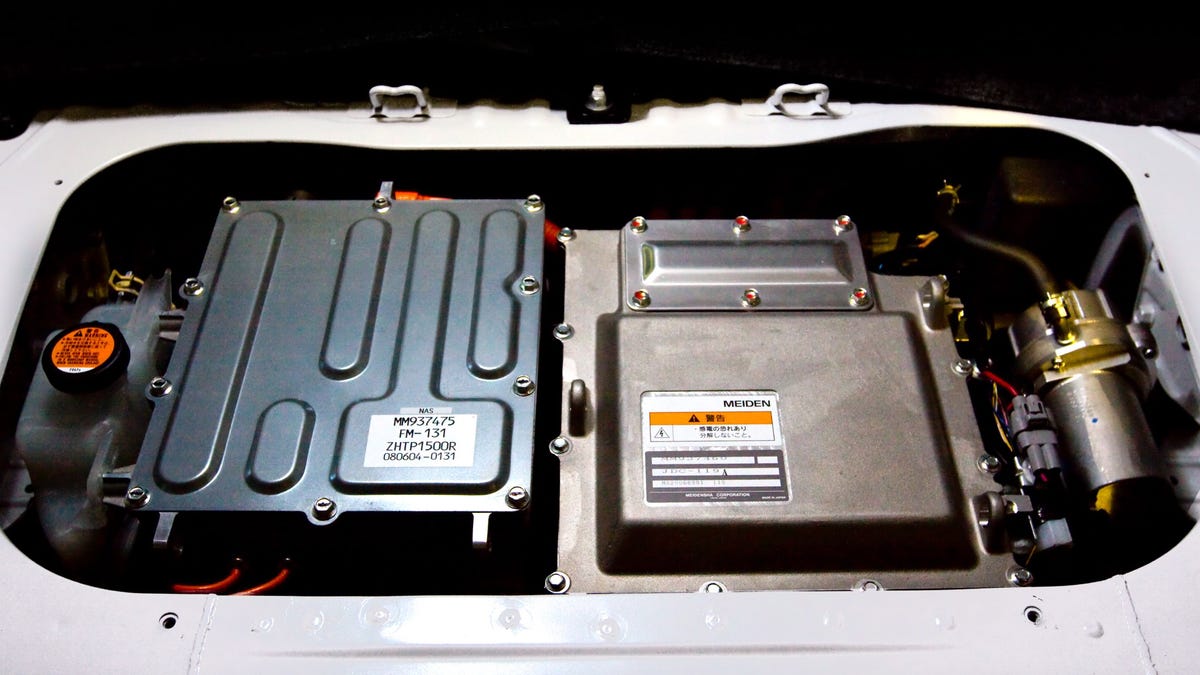

So what's being done to lower the cost of these vehicles? Manufacturing aid for electric car development is trickling out: Ford recently received $55 million in tax incentives from Michigan Economic Development Corporation to continue their research on advanced battery and electrical vehicle development, Tesla Motors announced approval of a $350 million loan to build an electric car plant from the DOE, and Nissan applied for a DOE loan to build a lithium ion battery plant in Tennessee.

Granting loans to build plants and fund research for a better, cheaper way to build lithium ion batteries may pave the way for additional technologies while firming up the U.S.'s image as a thought leader. However, not much is being done to make these car affordable for consumers.

Increased demand and mass production will likely bring down the cost of manufacturing the batteries as they did in the Prius, but they'll always be expensive because of the precious metals batteries use. For consumers to save money buying a Volt, production will have to increase to a million cars--lowering the cost of these costly batteries--and fuel costs must surpass $5 a gallon.

That strategy worked for the Prius, but Toyota had a boom economy, lax lending standards, and high demand for gasoline to help them move their vehicles. The current economy? Not so much.

This means that in the race to build a cheap lithium ion battery it's hardly a domestic versus import problem--it's a consumer problem. It doesn't matter from where or which company car makers source their batteries if no one can afford to buy them.

(Sources: BusinessWeek and AutoBlogGreen)