Why You Can Trust CNET

Why You Can Trust CNET XYZprinting Nobel 1.0 3D Printer review: Highly detailed prints at a high cost

Using a fascinating method to build very high-quality 3D objects, this is the first stereolithography 3D printer that's cheap enough for general consumers. Will it be worth the investment? Here's CNET's full review.

The Nobel 1.0 is unlike any 3D printer I've worked with before. It's the first stereolithography 3D printer with a price low enough for general consumers, costing $1,500. (Pricing for the UK and Australia will be announced at a later date, but that converts to around £965 or AU$2,065.) Though that's hardly cheap, it's by far the least expensive SL 3D printer on the market; others can cost twice the price or even much more.

The Good

The Bad

The Bottom Line

And if the price of the printer hasn't put you off yet, keep in mind that the consumables for this type of printer, namely the liquid resin, are not cheap either. The resin for the Nobel 1.0 costs $120 for 1kg (2 pounds).

In return, the Nobel 1.0 can print in extremely high detail and can print objects with overhang features that are difficult for fused-filament fabrication (FFF) printers -- which the rest of the 3D printers I've reviewed are -- to print. The Nobel 1.0 is also compact and relatively quiet during operation.

The new SL technology doesn't make the Nobel 1.0 print quickly. In fact, most of the time it takes longer to print an object of the same physical size than do FFF printers. This is because, as an SL printer, the Nobel 1.0 always prints solid forms while FFF printers can hollow out the thick parts. And that means the printer will use up materials much faster, increasing the total cost over time.

All things considered, I really like Nobel 1.0 for the way it prints -- which is as fascinating as pulling a solid object out of a liquid container -- and its print quality. However, considering its slow print speed, and most importantly its total cost of ownership, I feel that the printer is only suitable for 3D printing enthusiasts, and not for general use. For other options that are not as cool, but are faster and more affordable, check out our recent 3D printer roundup.

Compact design

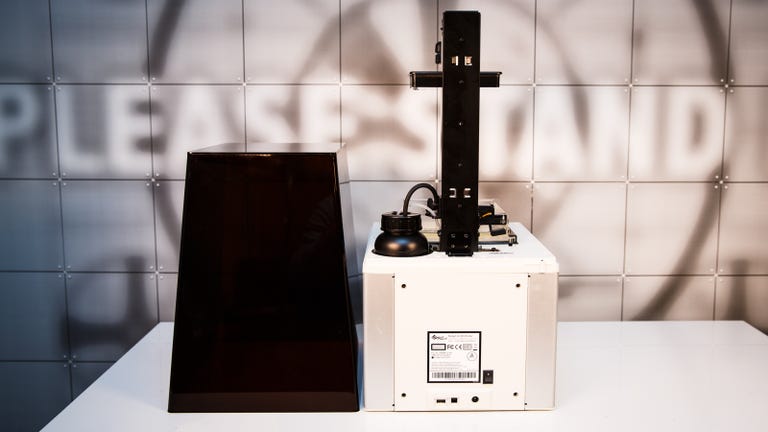

The Nobel 1.0 is compact, just about the size of a large home coffee maker. The company gives its dimensions as 11 by 13.2 by 23.2 inches (280 by 337 by 590 mm), and when I measured it myself I got similar figures.

On top the printer has a large black plastic hood that protects the print platform and the resin tank from the outside world. The printer needs to be covered up during operation (it won't work without the hood on), mostly to keep other light sources and dust from interfering with its laser beam. But when it's not running, you can remove this cover to add more resin, remove the printed object and clean up.

The printer comes already assembled. All you have to do is remove its packaging and install the included 500ml resin bottle as well as the resin build tank. It took me just a few minutes to do this thanks to the clear instructions included. During a print job, a pump will automatically fill the build tank with resin from the bottle.

The print platform is directly on top of the build tank and is attached to an arm designed to move it up and down. The build tank is made of glass and underneath it there's an ultraviolet laser beam that does the work of turning liquid resin solid. (More on how the printer works below). The print platform determines the size of objects the Nobel 1.0 can produce, which is objects of up to 5 by 5 by 7.9 inches (127 by 127 by 200 mm). This is quite large considering how compact the printer is.

Similarly to other XYZprinting 3D printers, such as the da Vinci Jr, the Nobel 1.0 has 2.6-inch LCD screen and six navigation buttons on the front. You can use these buttons to manage the printer, including replacing resin, viewing the printer's status and initiating a print job. The printer connects to a computer via a USB 2.0 port on the back. It doesn't feature an SD card but it does support printing from a thumbdrive, via another USB port also on its back.

Unlike FFF printers, the Nobel 1.0 has a simple initial calibration to ensure the build platform and the bottom of the resin build tank are leveled. All I had to do was follow the instruction on the printer's screen to move the platform all the way down until it pressed against the bottom of the tank. After that the printer was ready to work, and it did, without any hiccups or the need for further calibration.

XYZprinting Nobel 1.0 Specs

| Technique: | SLA (Stereolithography Apparatus) |

|---|---|

| Printer dimensions: | 11x13x23.8 inches (280x345x594 mm) |

| Weight: | 21.2 pounds (9.6kg) |

| Display: | 2.6-inch touchscreen |

| Light source: | UV Laser λ 405nm (100mW) |

| Connectivity: | USB wire |

| Build size: | 5 by 5 by 7.9 inches (128x128x200 mm) |

| Power requirements: | 100-240V 50/60Hz 60W |

| Layer thickness: | X/Y axis resolution: 0.3mm (300 Microns)/ Z axis: 0.025mm (25 Microns) |

| Print material: | Photopolymer resin |

| Resin supply: | Auto-refilling |

| Resin bottle capacity: | 500ml |

| Software: | XYZWareNobel |

| Operating system: | Windows XP (.Net 4.0 required), Windows 7+ (for PC), Mac OS X 10.8 (for Mac) |

| File types: | STL, XYZ format, GCODE |

Stereolithography 3D printing technology

The Nobel 1.0 uses stereolithography (SL) 3D printing technology, also known as stereolithography apparatus (SLA). In a nutshell, this technology works in the opposite direction from fused filament fabrication (FFF).

With FFF, the printer builds an object layer by layer from the bottom up on the print platform, similarly to icing a cake or using calking. With SLA, however, the printer's print platform dips itself into a container full of nothing but liquid resin and slowly pulls up a solid 3D object, upside down. Imagine you put your fingers into a cup of cocoa and slowly pull out a candy bar that has never been there before. It's kind of magical like that.

Technically, however, there's no magic. In the case of the Nobel 1.0, the print process is like this. First the print platform lowers itself into the resin glass tank, then an ultraviolet laser light, reflected from an actuated-mirror device underneath the tank, shines on the resin underneath the build platform. (For this reason, SLA is sometimes called the laser 3D-printing technology.) Exposed to the laser light, the resin cures, solidifies and sticks to the platform. As more resin is exposed to the laser light, the pattern is created and joins the layer above. As more and more layers are being created, the build platform slowly -- very slowly -- moves upward and finally pulls the entire object out of the tank when the print process is finished.

Another big difference between FFF and SLA 3D printing is that while FFF produces a lot of heat during a print (which is required to melt the plastic filament), SLA remains cool the whole time. Instead you have to deal with the liquid sticky resin, which can be messy. Also, while with FFF the 3D object is ready to be used right after the print, an SLA 3D object needs to be washed with strong solvent (over 75 percent alcohol) afterwords; otherwise, it will remain wet (and sticky) for weeks. This is the case with the Nobel 1.0.

XYZprinting says the resin used by the Nobel 1.0 is made mainly of acrylic monomer. It has a strong candylike smell and is not harmful to humans or the environment, though certain people might be allergic to it.

Familiar software

The XYZWareNobel software comes with the Nobel 1.0, and you can also download it (registration required). The software for the most part is the same as the XYZWare software used with XYZprinting's FFF printers. The only difference is that the software for the Nobel 1.0 doesn't include customizations that the printer doesn't support, such as the filling level. And thanks to SLA, the Nobel 1.0 can easily print objects with overhanging features, such as a robot with extended arms, without needing to make supports for the arms.

The software is easy to use: its interface consists of large and self-explanatory buttons allowing you to import and manipulate the 3D object files, and print directly to the printer. Once the print command is invoked, depending on the size and complexity of the 3D model, the software takes from a few seconds to a few minutes to transfer the data to the printer. After that, the printer can print on its own, without having to be connected to the computer. Alternatively, you can also load 3D model files onto a USB thumbdrive, connect that drive to the printer's USB port and use the LCD screen to print directly from there.

Note that the printer in most cases prints the object upside down, since effectively it pulls the object up from the tank of liquid resin as mentioned above. In the software, however, you should still work with the object in the normal orientation. If you manually flip the object, the print might fail because the printer will print the top part first, which might not have enough surface to stick to the print-platform firmly enough to hold the rest of the object.

The Nobel 1.0 supports standard and popular 3D model files. There's a huge collection of free 3D object models at Thingiverse that you can use, or you can make your own using software, such as SketchUp or Autodesk 123D. XYZprinting also has a large collection of 3D model files to choose from at no cost.

Performance

Despite using laser to print, the Nobel 1.0's print speed is definitely not that of a regular laser printer. In my testing, it was slower than FFF printers most of the time. For example, for a small round object that an FFF printer takes about an hour to build, the Nobel took almost 2 hours. This difference varied, however, depending on the objects. When I printed something thin, such as an iPhone case, the Nobel 1.0 was about as fast as the Da Vinci Jr. But when I printed an object with thicker parts, such as a little puppy, the Nobel 1.0 took much longer.

This is because the Nobel 1.0 can't hollow out the middle. With an FFF printer you can choose the level of filling from 10 percent (mostly hollow) to 100 percent (solid). But an SLA printer such as the Nobel 1.0 prints only solid forms, which not only makes it take much more time to finish an object, it also means the printer needs more materials than an FFF printer. Depending on the object, the Nobel 1.0 can use up to three times the amount of materials for the same object.

In my testing with a 500ml bottle of resin, I could print just three copies of the Incredible Hulk (see picture), while the da Vinci Jr could print about eight of them, each about 15 percent larger. With the bottle of resin costing about $60 each, effectively each Hulk print costs about $20 worth of materials with the Nobel 1.0.

Note that the Nobel 1.0 never uses up the amount of resin it has pumped into the build tank, either: the resin in the tanks needs to remain at certain level for the building process. In other words, once you've finished making an object, no matter how small, there will be about 50ml of resin left in the build tank, which will go to waste if you don't use the printer for a few days. So if you don't intend to print a lot of things, be prepared to waste a sizable portion of the resin.

On the other hand, the print quality of the Nobel 1.0 is significantly superior to that of any FFF printer I've worked with. Even at the Normal quality setting (which is the lowest and has a resolution of 0.1 micron), the printed object has incredible detail. The higher quality setting will increase the level of detail to up to 0.025 micron resolution. However, in this case the printer will take much longer to build the object.

In short, with the Nobel 1.0, you're accepting the expense of the material and the slow print speed in exchange for the extremely high-quality print. Also, since the resin is sticky, you will need a pair of gloves to work with the printer, especially when you remove the finished object off from the print platform. You will also need to rinse it with alcohol right away. In my testing, when left alone, the object would remain wet and sticky for longer than a week.

Conclusion

Despite being the least expensive SLA 3D printer on the market, the Nobel 1.0's $1,500 price tag still makes it cost prohibitive for most consumers. On top of that, the resin is not cheap, either, at $60 per 500ml bottle. And keep in mind XYZPrinting currently only sells the resin in kits of two bottles at a time, meaning in order to get more resin, you'll need to spend at least another $120.

However, my biggest problem with the printer is not the cost but its print speed. If the printer could print as fast as a regular laser printer, I would totally recommend it. Unfortunately, its print speed is disappointingly slow.

So at the end of the day, the Nobel 1.0 is an expensive 3D printer to own and its special capability of producing complex and highly detailed objects is outweighed by the cost. That said, if you're a 3D-printing enthusiast willing to spend the money, the Nobel 1.0 has its appeal. The combination of compact design, ease of use, high-quality prints and the fascinating way it build objects makes the printer a really fun and satisfying machine to have.

For those who just want to try out 3D printing, the Da Vinci Jr, the Da Vinci AiO 1.0 or the 3D System Cube 3 would be a much better choice. Though none of these FFF printers can produce a level of detail even close to that of the Nobel 1.0, they are significantly cheaper -- costing from just $350 to $800 -- and won't require you to clean the prints with alcohol.