Coming to a printer near you: Electronics manufacturing

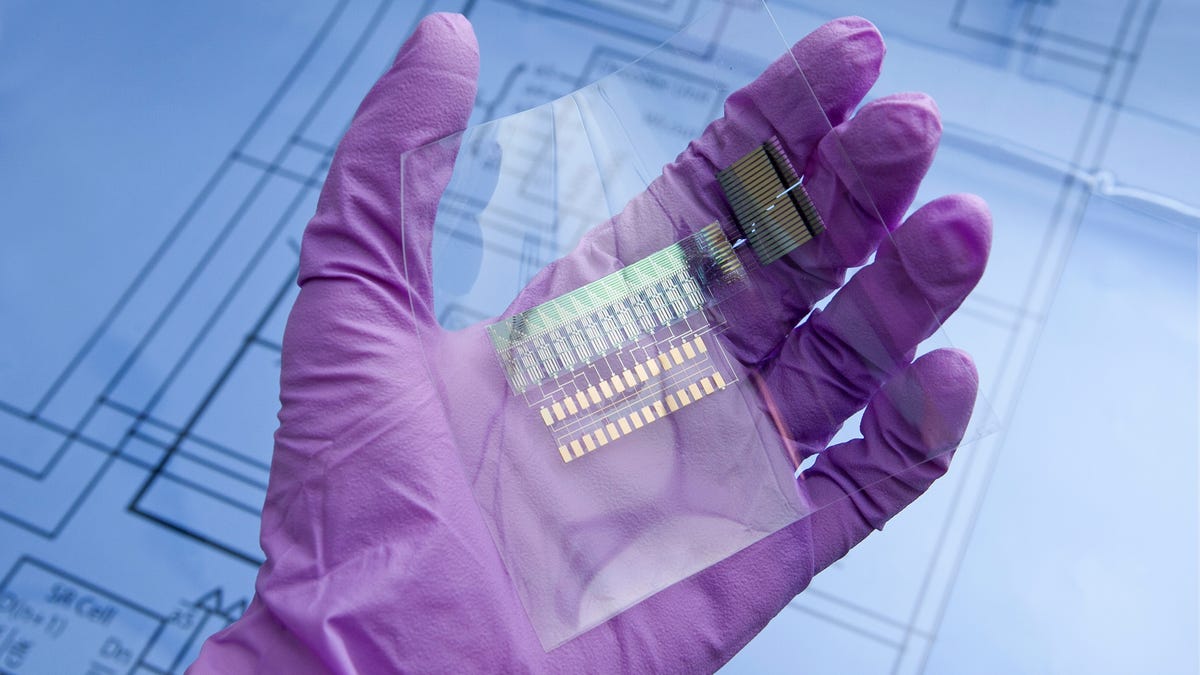

At PARC, researchers are developing a new technology for printing everything from transistors to smart labels to semiconductors.

PALO ALTO, Calif. -- Got a large roll-to-roll printer that you're not sure what to do with? You might have a future in electronics manufacturing.

It's still very early days, but researchers at the Palo Alto Research Center (PARC) have been taking significant strides in developing a new technology that makes it possible to print electronic components like sensors, transistors, light-emitters, smart tags, flexible batteries, memory, smart labels, and more.

PARC's work can also bring a new element to 3D printing: adding electronic, sensing or optical functionalities to parts. Printing electronics shares one major trait with that very hot technology: It is additive rather than subtractive. That means, said Janos Veres, PARC's program manager for printed electronics, that rather than etching the components out of other materials, the new system uses specially concocted inks to generate the electronics from scratch. Those inks may be composed of molecules, nanomaterials, and even tiny suspended silicon chips.

Though PARC is a division of Xerox, and often utilizes that company's decades of printing expertise, it is not developing the new technology for its parent. Rather, it is working in conjunction with private companies and academic institutions to try to break new ground in the field of printable, functional electronics. Ultimately, it is looking for partners with groundbreaking ideas on how to use the technology for functional products or prototypes. That means that the sky is pretty much the limit for what's possible. All that's required is imagination, Veres said.

At the core of Veres' work is a blending of material science and printing technologies. And that means developing a series of special inks that incorporate the desired functionality, be it sensing, light-emitting, or even chips. "You make inks and print with those inks," Veres explained. "And you only put it where you need it."

PARC is a fabled research institution, home to the very first graphical user interface, the first laser printer, and many other notable technological breakthroughs. And deep in its narrow hallways is Veres' lab, where he has a prototype electronics printer. Like others that are being developed in the field, this one features different print heads, each of which is used for making a different component. The idea, he said, is to be able to print an entire electronics assembly at once, with each head doing a different part of the job.

But while one method for printing electronics employs traditional InkJet print heads, other methods, such as gravure, and flexo, are being used as well.

Traditional electronics manufacturers have no need to worry for the health of their businesses just yet. Veres said that although he and his partners are making laudable progress, the state of printed electronics is akin to where transistors were in the 1960s.

And it's not entirely clear who will be the big users of printed electronics. On the one hand, Veres said, it's possible to imagine large fabs featuring the technology. But on the other, printed electronics could become the province of small manufacturers. Either way, he sees it being used by people or companies intent on adding "intelligence into printing," and will likely end up finding a home in both types of places. "We look at both as possibilities," Veres saod. "Like computing went mainframe and PCs."

One big advantage of printable electronics is that they can be made using large, wide transparent or flexible areas. That's where traditional roll-to-roll printers, often used for things like printing newspapers, can come in handy. Those machines are built to churn out nearly endless copies at hundreds of feet a minute. Instead of the daily news, they could now be useful for turning out large numbers of simple transistors or other components.

And this type of printed electronics would be ideal for a wide range of wearable devices, Veres said. Health tracking is an obvious application, he added, given how conforming thin plastic sheets can be, and how they can be molded into many different shapes, each with a potential different function.

But there are plenty of applications outside health care that make sense for the technology, Veres said. One example is a label with a built-in temperature sensor that's capable of, say, issuing an alert when the package of fish it's attached to rises above a desired temperature. And Veres added that the goal is to be able to incorporate these types of functional sensors directly into packaging.

That means that this is a very exciting time in the field. Veres said that what's happening right now is that PARC and its partners at universities like Clemson and companies like Thinfilm are developing libraries of functional printed electronics. Over time, as those libraries expand, more partners will likely discover ways to incorporate them. Gradually, Veres noted, these libraries will form the basis for a printed electronics platform