DIY robots: Print your own custom bots

An MIT-led project envisions people designing and having their own robots manufactured by a new generation of three-dimensional printers.

In the future, you may go to a "Robo Kinkos" store to have your robots printed.

The Massachusetts Institute of Technology today announced a five-year research initiative to let people design personalized robots and have them made with three-dimensional printers.

The ambitious project envisions a day where individuals choose from a set of templates to create a robot to solve a specific task, be it playing with a pet or measuring radon levels in a basement. It is funded by a $10 million National Science Foundation grant and includes the University of Pennsylvania and Harvard University.

"This is taking the app store to the next level," said MIT professor Daniela Rus. "To get the device, you push a button and return to the (printing) store later to pick it up. And the device would come with a customized programming environment."

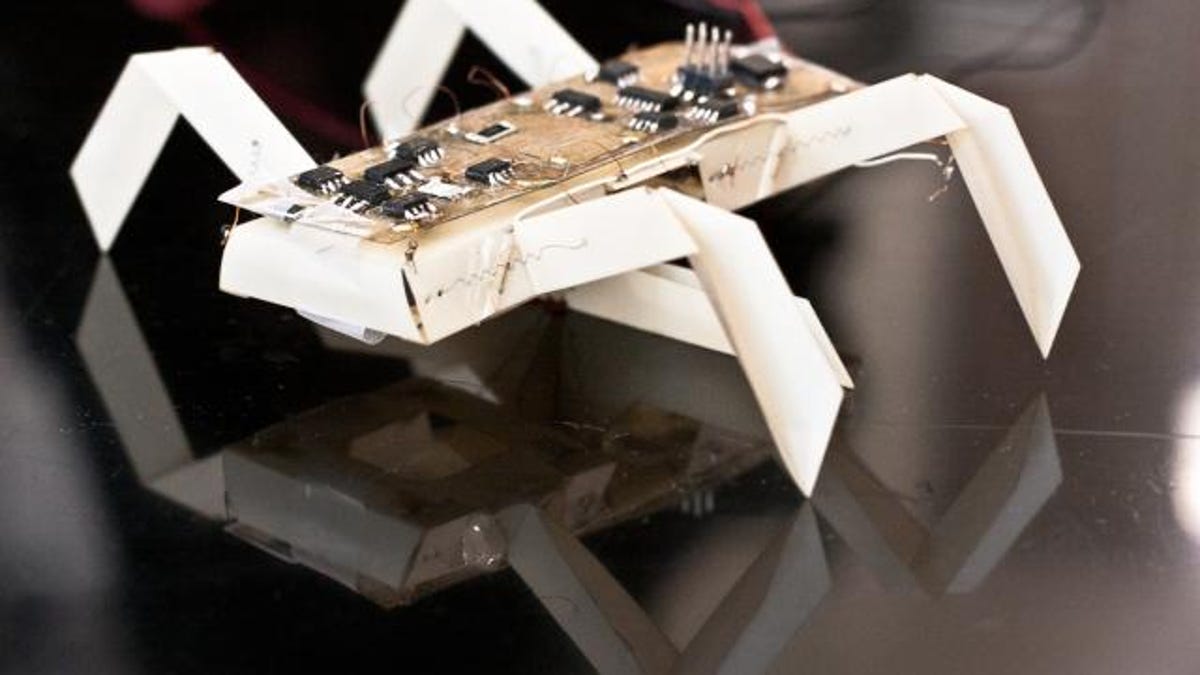

The research group has already created a couple of prototypes, including an insect-like programmable robot and a gripper, which cost less than $100 to make.

Realizing its vision of custom printed robots will require breakthroughs in three-dimensional printing, software simulation tools, and programming.

If it comes together, people will be able to look through a catalog of robot types and define a few of the device's parameters, such as the number or size of robotic insect legs. Once a software model is made, 3D printers would manufacture the device potentially in a few hours. These printing machines will need to use "smart materials" able to integrate the computerized control systems into the device's structure, Rus explained.

The device's programming environment would only control the actions of the individual robots and be easy enough for a non-programmers to use, she added.

"We hope to democratize access to programmable machines and robots," Rus said. "We're very interested in the idea of providing one experimental device per child and having inexpensive ways for kids to get excited about STEM (science, technology, engineering, and math) education and making their own devices for experiments."

In the health care industry, customized robots could aid people in wheelchairs reach objects in difficult places or make manufacturing more flexible by quickly making custom tools.

Over time, the researchers hope to create a database of designs which others can access for their own creations.

"The enabling technology has reached the point where it's possible to frame some of these questions," said Rus. "We're at a point now where the hardware and software advances (in robotics) are just exploding."