Thomas Jefferson: The Smithsonian's 3D printing pioneer

A new effort at the Smithsonian will create digital 3D models and physical 3D printed of many of the objects in its archives, a step that could help researchers and educators alike.

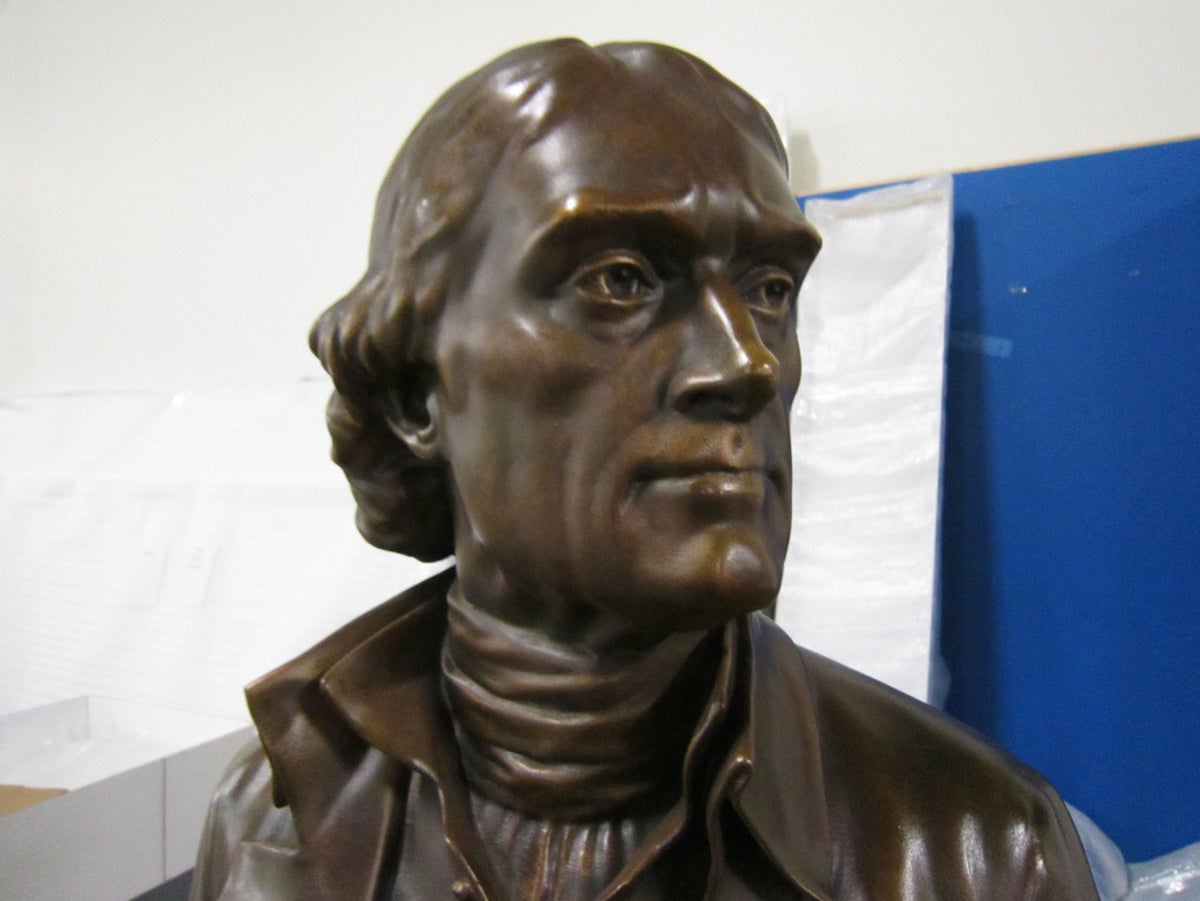

Thomas Jefferson in bronze face

The result? What the Smithsonian says is the "largest 3D printed museum quality historical replica" on Earth. And now, it's also the showpiece that begins a much larger effort at the world's biggest museum and research institution: a move to create digital 3D models and physical 3D prints of a wide variety of the objects in its archive.

This could have a profound effect if the effort is successful over time. Visitors to the Smithsonian's many arms see just 2 percent of its giant collection, and widespread digitization could mean that the archives are opened up--virtually, at least--to people throughout the country and the world. And that could be a boon to both researchers and educators, as well as students everywhere.

Plus, the museum itself is likely to be able to display a growing number of sophisticated 3D printed models and replicas, with Jefferson being just the first example.

Jefferson's legs

Jefferson in parts

Upper body