[MUSIC]

Corning's glass has been helping to shape the way that we interact with technology for decades.

It's the window covering many of the screens we look at on a daily basis and it's the armor that protects our phones from these types of falls.

[MUSIC[ As technology has evolved, the glass has had to evolve right alongside with it.

And though the use cases may have changed, the one thing that remains the same is that the display is still one of the first things that users are interacting with.

So today, we're here to see how the glass itself is helping shape the next generation of devices.

We took a trip to Corning's headquarters in New York to find out what the makers of Gorilla Glass are cooking up next.

[MUSIC]

Glass is made up of two basic ingredients, sand and a whole lot of heat.

But add anything else to the mix and you're left with a totally different type of glass.

IN fact, even changing the baking temperature or the cooling time can drastically alter its properties.

If you think about all the dimensions of glass, its optics, its chemical composition, its physical properties, its electromagnetic properties, we're learning how to control all of those in incredibly precise ways.

This is Corning's test kitchen where new glass recipes are baked at temperatures of over 1,000 degrees celsius, hotter than molten lava.

Their latest recipe, ultrathin bendable glass.

As the Foldable phone space heats up with companies like Samsung and Royal entering the market.

Corning continues to push the envelope on how much glass can bend.

To go to type and radius, you have to go a glass that's much much thinner than what you have today.

And some of the glass we have in our laboratory is

Thinner than a human hair.

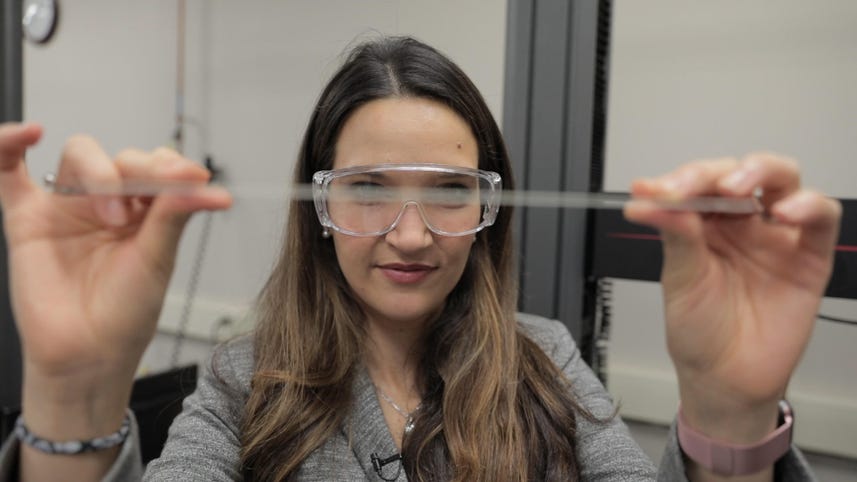

We got an early look at Corning's ultra thin, bendable glass.

And though we werent' allowed to film it, this is Corning's footage of what it actually looks like.

It's not their first bendable glass, but it's a lot thinner, and a lot more flexibile than the Willow Glass they introduced a few years back.

It bends to a five millimeter radius and the texture feels more like thin plastic then a sheet of glass.

This glass is still in development which means you won't find it on any foldable devices yet but [UNKNOWN] is ready to start working with it's customers to implement it into future designs.

The [UNKNOWN] opportunity is a little bit of a moving target now because of use cases isn't quite clear how people are gonna use these devices.

And the form factors are still evolving, whether it's gonna be infold or outfold or trifold, or small radius, or large radius.

But the future of glass is not just about foldables, and it stretches well beyond phones.

In fact, last May May be taking the driver seat when it comes to automotive design.

Corning has also been working on curve dashboard displays, textured glass that can mimic different car surfaces and anti-reflective glass that would reduce glare and make fingerprints disappear.

Inside the car, many syrfaces, almost all the surfaces inside that vehicle have shape, have form, except for this display And so what designers are looking to do is to be able to bend those displays around the user.

The driver around the passengers.

With Corning's new glass, everything from the car windows to the car consoles can become usable displays that seamlessly blend right into the interior of the car.

Manufacturers like BMW, Ford, and Porsche have already started using some of their glass in newer car models, with more to come in 2019.

[MUSIC]

And Corning's just scratching the surface when it comes to the possibilities of glass in new technologies.

So far, scientists have incorporated about 50 elements from the periodic table into silica.

But essentially, the entire period table is available, and I really think that we're just getting started.

And to think about the potential of using the periodic table.

Think about holding the Oxford English Dictionary in your hands and how many words you can make with only 26 letters.

[MUSIC]