[MUSIC]

We've been hearing for years about how 3D printing is poised to revolutionize car manufacturing.

But it's still hard to grasp just how this rapidly maturing technology will up-end the status quo.

[MUSIC]

That's why I'm here at Ford's Research and Innovation Center in Dearborn, Michigan.

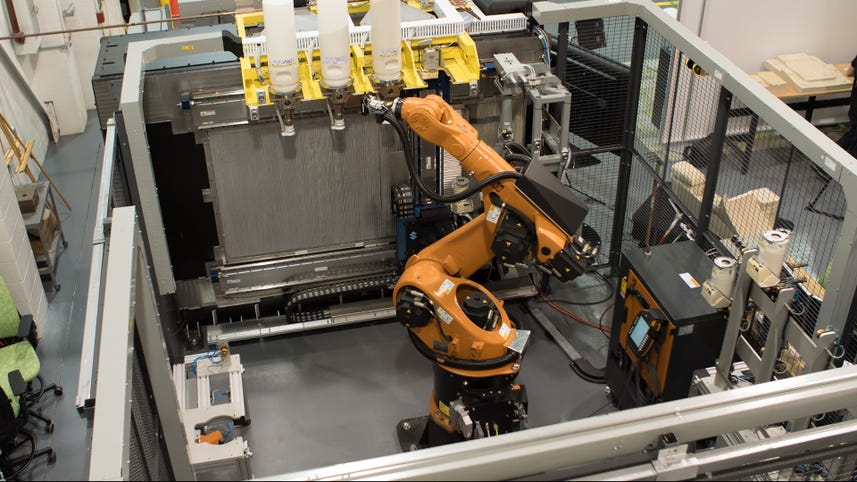

To check out the company's new Stratasys Infinite Build 3D printer.

This isn't just the company's most exciting new toy, it's got the potential to turn car design and manufacturing on its head, or more accurately, on its side.

When you think about 3D printing, you probably picture a small horizontal platform.

Upon which material is repeatedly layered to create something.

The problem with that setup is that you can only build the object so high.

The genius with the stratasys prototype machine is that it prints sideways, allowing for the creation of much larger objects.

Ford is among the only companies to have access to this equipment.

Boeing is also working with Stragasys to investigate the technology's potential for aerospace.

And some trial work is being done in the medical field now too.

The blue oval has only had this machine since November and right now it's still learning the machines capabilities and quirks.

Trying to figure out how this tool can help develop better automobiles.

This machine, what it does, is it takes that concept of this horizontal table, and it turns it up 90 degrees on its side.

And it actually extrudes into the table from a horizontal feed.

The other difference with this technology is the material supply, which is a very critical part of it.

With conventional FDM machines Strategists' machines they use a filament to feed the material in.

The filament is almost like a line from a weed whip that type of material.

With this process it actually uses an micro pellet so the material looks a lot more like a very coarse powder.

Because of that, this system is able to run for extended periods of time.

The robot that we see here in the background is actually used for changing material containers.

So, when the machine uses up a container material, the robot can actually reach up, remove that container, and put a new container in it's place.

So it enables the machine to run continuously uninterrupted.

Trying to figure out how many ways we can use it, what types of applications that we have in a big company like this, that's the biggest challenge.

I think there's a lot of flexibility in what we can do.

It can apply to manufacturing, prototyping, eventually to production, and touch pretty much every part of the vehicle.

So that's really exciting to make our processes a lot more efficient and more stylish.

So I think that there is a lot of excitement within the company because of the capabilities that it adds that we have not had before.

There's definitely a learning curve at work Fords lab coats have already figured out that certain things are best printed out in certain orientation.

And sometimes the machine can get lost and they [UNKNOWN] start a section over again.

It's early date for this prototype tech so all of this is to be expected.

It's not hard to envision machines like these helping to print not just prototype parts for concept cars or tool and [UNKNOWN] or multiple production plans but also eventually small volume parts for competition cars.

Cars.

Imagine Ford's GT WEC race car needs a new front splitter or wing for a particular race track.

Engineers will soon be able to model the part on a computer and three print it in a matter of hours or a couple of days, instead of waiting weeks or even months.

Eventually Ford helps 3D print signatures to the point where it can support big value production Helping to develop lighter-weight parts for cars and trucks.

Who knows, maybe this tech will one day speed up the design and production process, to the point where yearly vehicle face-lifts can become commonplace again, or perhaps to where individual owners can customize their cars.

Ford Stratasys 3D printer is still very much in beta And its researchers are just now starting to figure out what this incredible additive manufacturing toolbox can do.

The hope and increasingly the plan is to use it to develop processes, tooling, and hard parts to bring cooler, more versatile vehicles to your driveway sooner.

[MUSIC]

And for less money.

[BLANK_AUDIO]