Why You Can Trust CNET

Why You Can Trust CNET Afinia H-Series H479 review: An approachable, powerful 3D printer

Afinia strikes the right balance between performance and approachability with its H479 3D printer.

Of the three 3D printers I've used so far, the $1,599 Afinia H-Series H479 is my favorite. That doesn't mean it's perfect, but it's a more precise, and more flexible machine than 3D Systems' first-generation Cube printer, and it's significantly easier to use than the first-generation MakerBot Replicator.

The Good

The Bad

The Bottom Line

The high price of this printer will remain an issue for many consumers. Post-print cleanup with certain materials can also be a hassle. The fact that you can achieve good prints so easily and so quickly, though, makes the H479 easy to recommend. If you're willing to spend more than $1,000 on a 3D printer, the Afinia H479 should be at or near the top of your list.

| Printer | Afinia H-Series H479 | 3D Systems Cube (2013) | 3D Systems Cube (2012) | MakerBot Replicator (2012) |

|---|---|---|---|---|

| Price (at time of review) | $1,559 | $1,299 | $1,299 | $1,799/$1,999 w/ dual extruder |

| Material(s) supported (officially) | ABS, PLA | ABS, PLA | ABS | ABS, PLA |

| Build platform size | 5x5x5 inches | 5.5x5.x5.5x5.5 inches | 5.5x5.x5.5x5.5 inches | 8.9x5.7x5.9 inches |

| Minimum layer height | 150 micron | 200 micron | 200 micron | 150 micron |

If the H479 looks familiar, it's because Afinia licensed the design from Chinese manufacturer Delta Micro Factory, maker of the UP! 3D printer. You can find the Up for sale from various international resellers, including U.S.-based PP3DP. Afinia's version looks similar to the Up printer, but the H479 ships as a fully assembled product, and, according to Afinia, has improved wiring to minimize static shock.

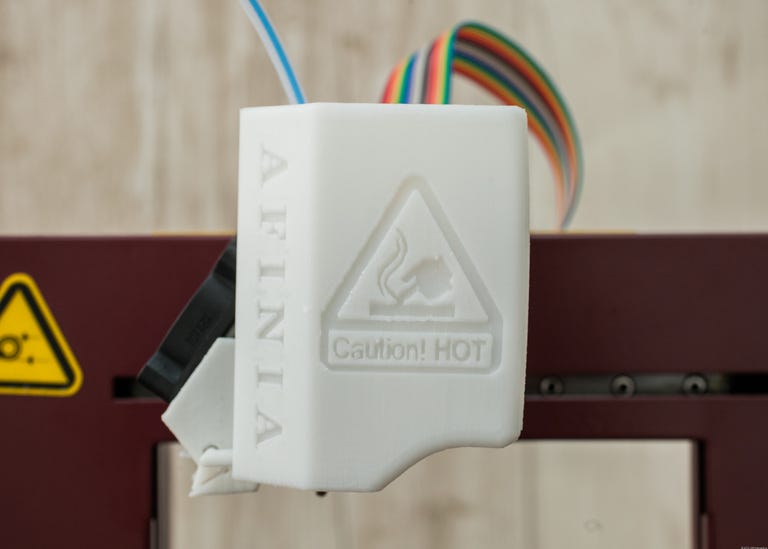

In outward appearance, the H479 fits somewhere between MakerBot's plywood-framed Replicator and the injection-molded plastic chassis that houses the 3D Systems Cube. It looks for the most part like a professionally made product, with a folded steel housing painted a pleasing dark red. An exposed ribbon cable leads up from the internal electronics to the extruder head, which looks a little unfinished.

More incongruous with the idea that this is a professionally manufactured product are the extruder cover and fan mount, a cable clip on the back on the printer, and the arm for mounting the spools of printing material, all of which are made themselves from 3D printed plastic. Downright amateurish are the binder clips you use to secure an included special printing surface to the printer's build platform.

The 3D printed parts look a bit rough, but they're all functional, and I've had no trouble with them after using the H479 for over a month. I suppose there's something thematically appropriate (and also cost-saving) about incorporating 3D-printed hardware into the printer. The open-source RepRap 3D printer project relies almost exclusively on printed structural parts for its designs.

Picky consumers might balk at the unfinished-looking printed components. The binder clips, like the cruddy rubber tubing that serves as "feet" for the MakerBot Replicator, are a bigger offense. They suffice, and they're easy to replace, but a purpose-built mechanism would be more appropriate to a finished consumer product.

In addition to the printer, inside the H479's packaging you're met by a 1.5-pound spool of ABS plastic filament to print with (in my case, blue), and a box of accessories. Afinia deserves credit for supplying you with almost every conceivable tool you might need to interact with the printer and your prints. Included are an X-Acto knife and an assortment of blades, a sharpened scraper, a giant pair of tweezers, a small socket wrench, a pair of snipping pliers, three hex wrenches, a plastic tube, and a pair of work gloves, along with the power brick, power cables, and a USB cord.

Why do you need all of those tools? For initial setup, you only need the hex wrench, which you use to attach the plastic support arm that holds the filament spool. The rest of the tools come in later.

The remainder of the setup process more or less follows that of other 3D printers, with a few exceptions. A one-sheet quick-setup guide gives you the basics. The box also contains a longer manual.

Unlike the MakerBot and 3D Systems printers, the H479 has no built-in control, nor can it read design files from a USB key or an SD card. The H479 does have built-in memory, which means that while you need a PC or Mac for setup and to send files, you can disconnect the PC once the print is in progress. Other vendors like to tout their products' ability to print without any help from a computer, but I'm not sure how important that capability really is to most users.

I connected the H749 to a Windows 7 PC and both the printer and the software worked as expected. Afinia's software embodies a reasonable compromise between ease of use and the power to customize printing options. It could be a bit more intuitive. The calibration and support-material option screens in particular are difficult to understand without reading the manual. Advanced users might also wish for more granular control, like the option to turn off support material (coming in a future update, says Afinia), or to load settings profiles to the printer.

One useful feature of the software is that it tracks material usage. If you tell it how much your spool weighs when you first load it, it will log how much material you've used from that spool from print to print. This is handy for a number of reasons, among them that it enables the printer to tell you if you don't have enough material left to print a certain object.

Overall, Afinia's software is better than that of 3D Systems, but it doesn't seem as powerful as MakerBot's MakerWare. Afinia does many things 3D Systems didn't do in its first-generation Cube software--letting you customize object density, print resolution, and the characteristics of the support material, for example. MakerWare, on the other hand, does that and more in its Advanced Settings.

Good PC software is particularly important for the Afinia printer, because it drives all of your interactions with the printer, from loading the printing filament to dealing with the extruder to leveling the build platform and calibrating the nozzle height. The setup sheet walks you through all of those steps. The last two are the only ones that take a significant amount of time, and they're similar to the same processes on the Replicator, requiring you to manually adjust a series of screws underneath the build platform, and then gauge the space between the nozzle and the platform with a piece of paper.

When you finally do use the software to guide you through loading the print material, you can choose to set the printer for either ABS or PLA plastics so that it knows what temperature settings to use for the extruder. Unlike 3D Systems Cube and CubeX printers, the H479 can print with any spool of 1.75-millimeter filament. Afinia recommends you purchase plastic directly from it, but I tested the H479 with ABS from MakerBot, and a spool of ABS from an online retailer, as well as Laywoo-D3, a wood-and-polymer based material (the PLA setting worked fine here), all of which printed with no clogs or other problems.

The automated temperature control is convenient, and it does work well enough. True granular control of the extruder and build platform temperatures would be preferable, though.

Manipulating 3D model files in the Afinia software is also easy. You can send common STL files directly to the H479, saving you file conversion time and the added complexity that comes with 3D Systems' proprietary file format. The 3D representation of the model on the virtual printing platform makes sense, and the real output matches what you see onscreen.

Afinia makes it easy to add additional copies of a model, via an Insert Copy function. You can also load a different model to the same print, and the software automatically arranges the models on the platform. True manual placement control seems to be absent from the software, but the automated function worked well.

The biggest shortcoming of the Afinia software is that it forces you to have some kind of support material on overhangs. You can minimize the support to overhangs of only 80 degrees or greater, but even then, over a small-enough span you don't always need support. The support material is generally easy to remove, but not always, and a particularly fragile or complex object might not survive the removal process. Afinia says the option to shut off support entirely is one of its more requested features, and that a software update is in the works.

When you finally execute a print, Afinia's software performs the "slicing" (translating the 3D model to layer-by-layer coordinates for the printer) itself, keeps track of the layer in progress while you're printing, and provides an accurate time estimate before you confirm.

The quality of the output from the H479, as with other printers, depends on a multitude of variables, including the material, the model, and the settings you choose. Each material has its particular quirks, but in general the H479 makes the best prints I've seen from a 3D printer costing less than $2,000.

One of the trickier problems in 3D printing is ensuring that the object sticks to the build platform throughout the course of a print. Heating the platform so that the plastic retains its adhesiveness is part of the solution, but maintaining a high-enough temperature throughout a multihour print can be a challenge. Vendors rely on a variety of tricks to deal with this issue -- MakerBot uses heat-conductive Kapton Tape on its Replicator, 3D Systems uses a water-soluble glue -- but neither method is foolproof. Objects can peel up from the edges, or dislodge from the platform entirely.

Afinia's method with the H479 is not perfect, but it's one of the more reliable designs I've seen. Included with the printer are three FR-4 perfboards, the same stuff you use to make circuit boards. To use the perfboard on the H479, you clamp it on top of the metal build platform with the included binder clips. Again, the clips work well enough, but they do take up some build area. You also need to be careful to make sure the extruder doesn't travel over them during a print. It's for these reasons, more than their garage-hack aesthetic, that a purpose-made clamping solution would be better.

For model adhesion, though, the perfboard works amazingly well. It's the only solution I've seen so far that eliminates peeling over the course of a long print. You can always clamp the same perfboard to one of the other printers and calibrate your nozzle height accordingly, but Afinia makes this easy by including three boards in the box.

The downside of the perfboard technique is that it means you often have a lot of post-print cleanup to deal with. Because the print material fills the perforations, when you pry your object off, the surface resting on the platform will have lots of little posts attached to it, which you then need to scrape off. Printing objects with a raft -- laying down a few layers of plastic as a bed on which to print your object -- can eliminate this effect, but due to Afinia's aggressive raft settings, you then have to scrap the raft itself from the object, which also gives you an uneven bottom surface.

Removing the posts or the raft material can be a hassle, or even fatal to fragile prints if you're not careful. All those tools and the work gloves included with the H479? You will mainly use them in this post-print cleanup process, scraping, prying, and slicing support material and raft material away from your printed object. Even with the tools, your prints don't look as polished as they might if you printed them directly on a smooth surface. If you want a 3D printer for mere functional parts, this rougher finish shouldn't be an issue. If you're looking for output with a more professional look to it, you can look into sanding, buffing, or treating any rough surfaces with acetone.

Afinia says that you can print on the H479's build platform directly if you use painter's tape, but for me that introduced the same adhesion issues that I found with the MakerBot Replicator. I would much rather deal with the post-processing than worry about whether the print will stick. Just be ready to give your objects some post-print TLC, and you'll come to love the perfboard.

The other thing you will love about the H479, especially if you've used another 3D printer, is how quickly it becomes ready to print. Part of this is a function of the perfboard: because it saves you from waiting for the build surface to come to temperature, you only need the extruder to heat up, which happens very quickly. One of the more painful quirks of the Replicator is not only that it can take forever to come to temperature -- 15, 20 minutes or more depending on the ambient temperature of your work area -- but if it can't hold that temperature, you've only waited long enough for a botched print that won't stick to the platform. With the Afinia and its perfboard, printing starts quickly, and when it does you know your print will stay put.

The time required to actually make a print with the H479 will vary with the size of the object, how densely you choose to print the interior material, and the quality of the exterior, as usual. Afinia has quality settings, Normal, Fast, and Fine, which regulate extrusion speed. Generally, the slower you print, the better the output quality. For layer height, the H479 deposits material in .15mm, or 150 microns. That's not as detailed as MakerBot's most current 3D printer, the 100 micron-capable Replicator 2, but that printer sells for $2,199, and supports only PLA.

Conclusion

3D printer vendors often promise consumers a push-button future of effortless object making. This is not the reality for any 3D printer I've used or seen, including the Afinia H479. Where this printer does deliver is in its deft balance between ease of use and output quality. Yes, you need to put time into cleaning aggressive raft and support material, or the perfboard residue from objects printed without a raft, but overall the output is sufficiently precise, and prints for the most part are easy to clean up.

Among other printers that have not made it through our lab, I have not yet tested the 2013 edition of the 3D Systems Cube, nor the more recent Replicator 2. The new Cube in particular might give the H479 some competition in terms of usability, but as long as 3D Systems relies on its proprietary filament cartridges, open-feedstock printers like the H479 will remain the better economic bargain in the long run.

In terms of up-front costs, though, the Afinia H479's $1,599 asking price will be a challenge for many would-be 3D printer owners. You can find a much cheaper entry-level 3D printer, but in its $1,000-to-$2,000 price range, the H479 is one of the best.