MakerBot Replicator 3D test print gallery

I attempted about 30 prints during my review of the MakerBot Replicator 3D printer. These are their stories.

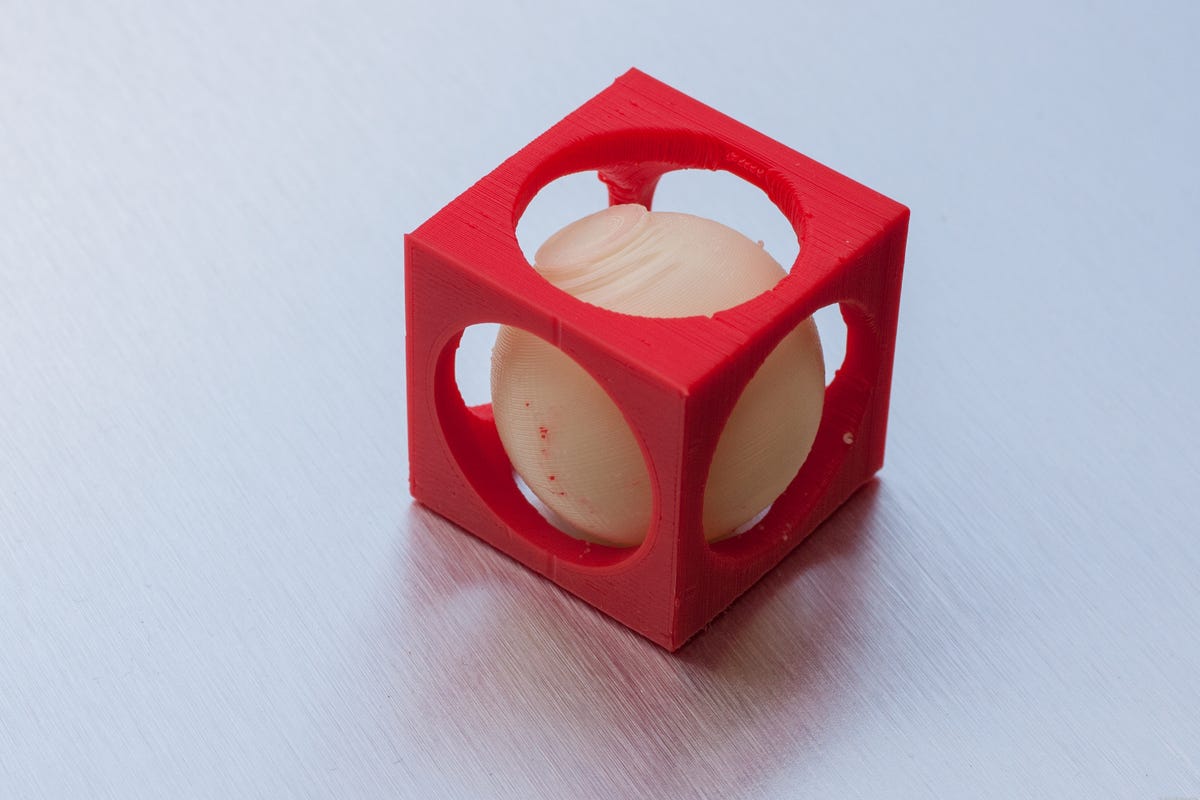

Dualstrustion Ball in Cube

Following are the majority of the designs I printed (or tried to print) during the course of reviewing the MakerBot Replicator. Most I obtained through Thingiverse, MakerBot's community-driven repository of 3D object design files, all of which are available to download for free. With 15,000-plus design available on Thingiverse, I barely scratched the surface of its content.

Of the files I pulled from Thingiverse, this is the most impressive item I printed successfully. The cube-shape and the ball come out in a single print thanks to the Replicator's dual-extruder printer head (or "dualstrustion," as MakerBot likes to call it). Design by etrohn at Thingiverse.com. This would make a great cat toy.

Klein Bottle/Mobius Vase

CNET Logo

Twirl Mini Moustache

Shark trial

The inside of each shark is only filled 10 percent of the way to save on plastic. I'm interested to know if the bit would come out more cleanly with a denser infill.

Calibration cubes

2 Color Mix Test

Duckbox

Duckbox 2

Castle

Spiral Box

Failed print graveyard: Windsor Chair

I hope to figure out how to print this chair eventually. Its design, by Thingiverse user PrettySmallThings, is beautiful.

Failed print graveyard: iPhone case

Failed print graveyard: Metratron (part 1)

Like some prints with large overhanging portions, the Metatron requires that you print it with a support structure, which you then break away after the print. Thankfully, the ReplicatorG software calculates the support layout for you when you have the option selected.