Behind the scenes at MakerBot (photos)

The 3D printing for the masses company turns out between 30 and 40 of its Replicators per day, and that number is about to double. Prepare to hear your neighbors talking about 3D printing.

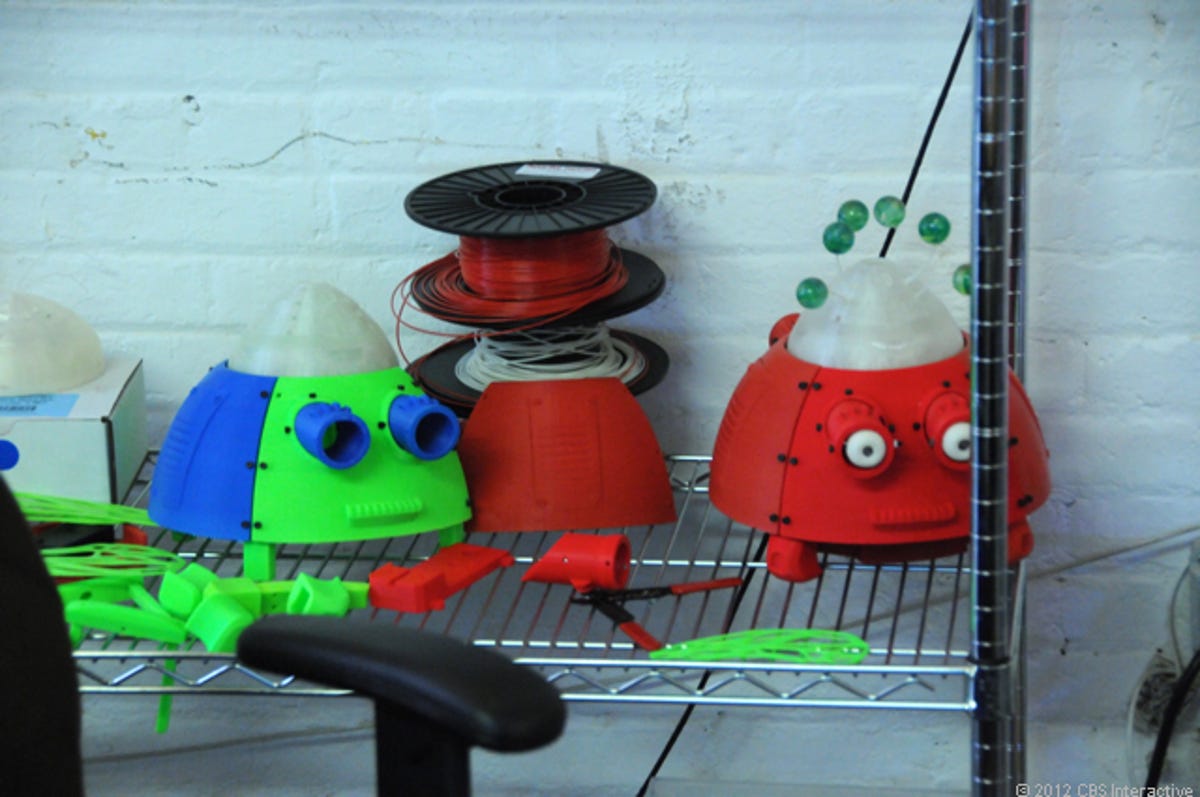

Petting zoo

At the company's offices, dozens of Replicators are humming at any given moment, churning out all kinds of 3D printed objects. Many are simply test objects to make sure the devices are properly aligned and ready to be sent off to a buyer. But right now, the company is also slowly turning out the parts for its first-ever "Robot Petting Zoo," a display that will make its debut at Maker Faire in San Mateo, Calif., next month.

On a shelf at the company's Brooklyn offices, workers have stored a number of 3D printed robots, each of which is awaiting the thrill -- if robots can have such emotions -- of delighting kids and adults alike at Maker Faire.