USS Gerald R. Ford

CVN 78

Under construction

Bow unit in place

787 metric tons

In dry dock

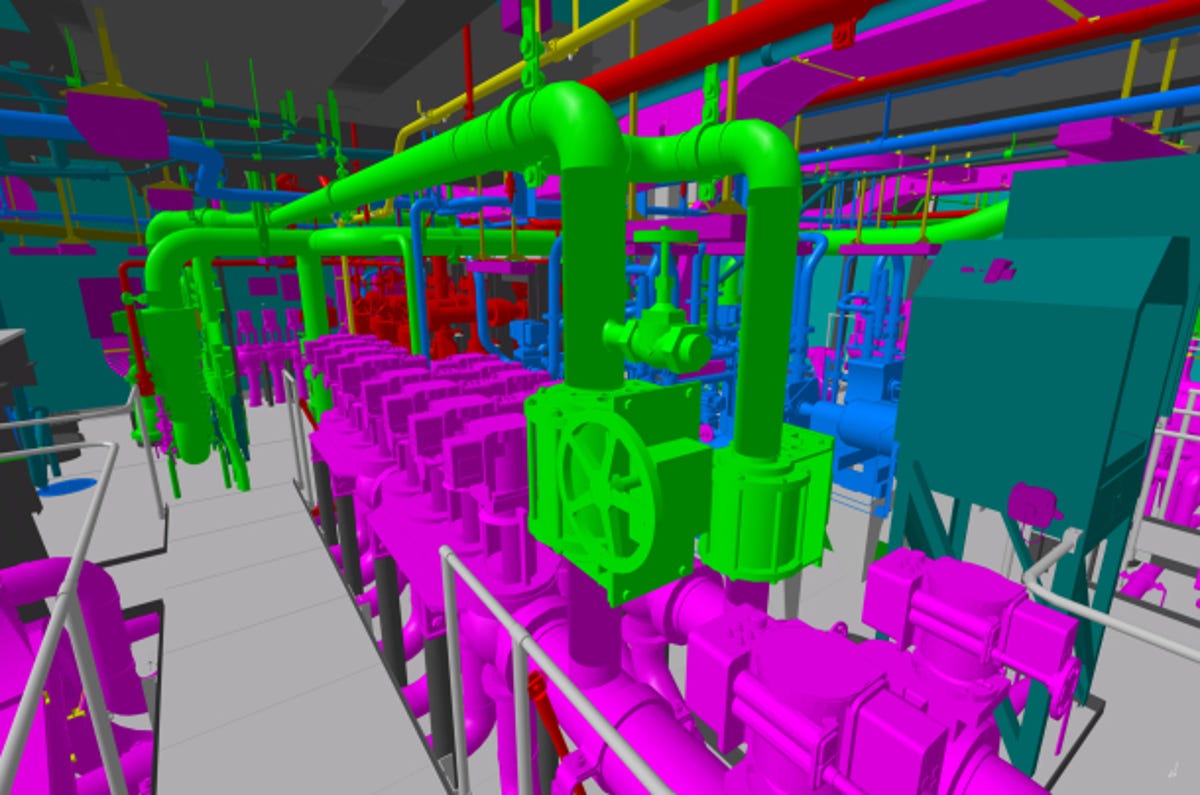

Pump room visualization

The software is particularly useful to the U.S. Navy and to the shipbuilder because it allows every stakeholder in the carrier's construction -- the Navy, the shipbuilder, welders, pipefitters, contractors, and others -- to see the plans in 3D before construction. That makes it possible for the first time to eliminate many inefficient designs that traditionally slow down ship construction. That's because each stakeholder can weigh in in advance on how others' plans will affect their work. For instance, a stakeholder might inform another that their piping plans are a problem because they would make it difficult to take out parts for maintenance without needing to cut holes in the ceiling. Previously, that hole most likely would've been cut. Now though, they avoid that problem altogether. It's hoped that by the end of construction, this process will have saved 2 million man-hours of labor.