Silevo's hybrid solar cell challenges status quo

Startup comes out of stealth with solar cell technology rooted in the 1970s and designed to lower the price of solar to $2 per watt installed, well below today's costs.

Much like a hybrid car, Silevo's solar cells use a few engineering tricks to boost overall performance beyond the oft-touted cell efficiency.

The 4-year-old company today detailed its technology, claiming it will be able to outperform incumbent Asian solar panel manufacturers on efficiency and industry cost leader First Solar.

The company has a research facility in Fremont, Calif., and has plans to build a demonstration-scale manufacturing plant in Hangzhou, China, to validate its technology next year, said Chris Beitel, the company's vice president of marketing and business development. The factory will be able to produce 32 megawatts worth of capacity and be financed by a $33 million investment led by Chinese venture capital company NewMargin.

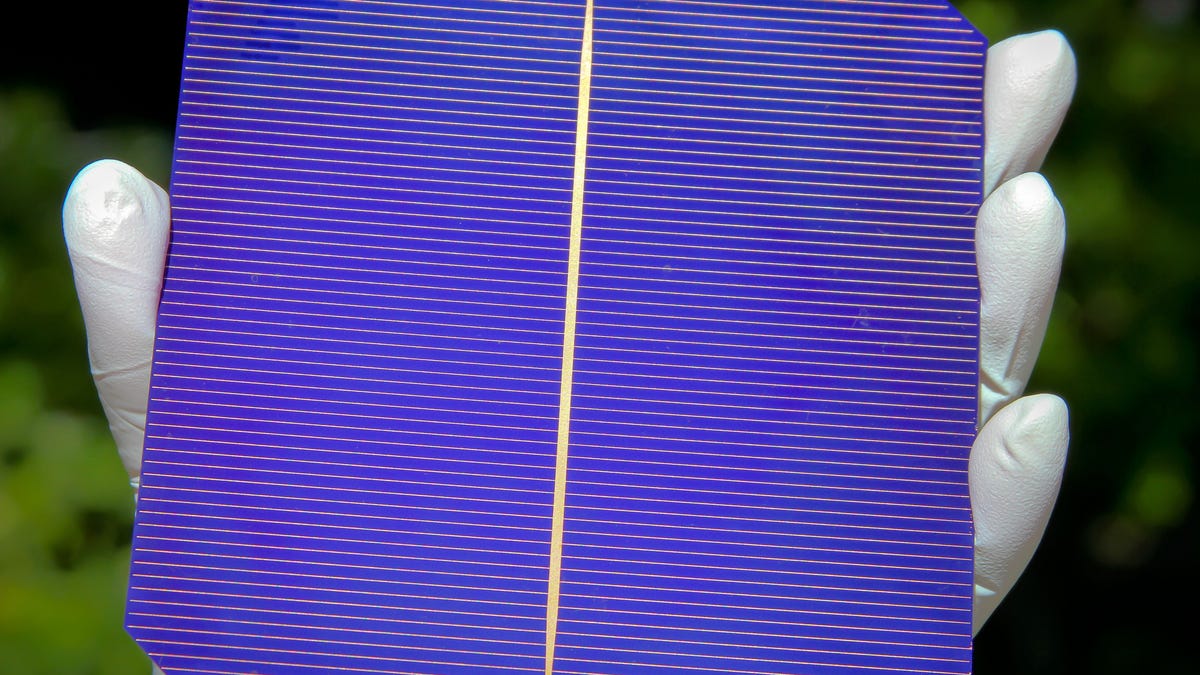

Silevo's solar cell architecture, called Triex, is built around a base of monocrystalline silicon wafers but then its manufacturing process includes additional layers to boost efficiency and energy capture.

A "tunneling oxide" layer of silicon dioxide is grown onto the silicon substrate to improve the cell's durability and efficiency. And then the wafer gains a thin-film passivation layer that increases the voltage, and thus the current, from the cell.

Its cells are able to convert about 20 percent of sunlight to electricity, far higher than thin film cells and in the range of high-end silicon panels from SunPower. The cell structure also means that the performance of solar panels will degrade more slowly than other technologies from heat, explained Beitel.

Like all electronics, solar cells work best in cool weather and their ability to generate electricity degrades with higher temperatures. Beitel said Silevo's cell technology has about the same degradation rate at First Solar's cadmium telluride thin film cells and substantially better than typical silicon cell manufacturers.

Borrowing techniques from the semiconductor industry, the company has also designed cells which use copper wiring, rather than silver, which reduces costs.

• Solyndra's burnout burdens other solar upstarts

• Multilayers solar cell boosts efficiency

• Alta Devices lifts curtain on high-efficiency solar cell

The company's target is to produce at $1.10 per watt when it starts producing in China in the first half of 2012. With improvements in the thin-film passivation, Silevo expects that efficiency will improve to 24 percent and costs can go down to 69 cents per watt with large-scale manufacturing.

The science behind the company's technology has roots in the 1970s, but company engineers have been able to use less expensive and stable materials, Beitel said. The company received $3 million in research funding from the Department of Energy.

Initially, Silevo is targeting residential solar installers as a way to sell its panels. Then, as the technology becomes more proven and it ramps up manufacturing scale, it expects to target commercial and utility-scale solar installers.

Its factory will use modified equipment from the solar and the LCD TV manufacturing industry, Beitel said. The company chose to manufacture in China because it will help it undercut other solar companies on cost and achieve $2 per watt installed cost, he added.

Updated at 9:25 a.m. PT with a correction to size of the Department of Energy loan.