Cracking the code on a cheap, reusable coronavirus mask

BioAid claims to have an innovation that could blend N95 filtration with easy cleaning for reuse.

San Francisco startup BioAid says its N95 mask design uses less filter material than a typical N95 mask and is conservatively reusable 30 times.

Cloth face coverings are good at containing your exhalation of virus particles and are easy to clean, while N95 masks can also protect you from inhaling microbes but are generally designed for single use. San Francisco startup BioAid says it may have found a blend of the two.

The latest BioAid mask is comprised of a see-through plastic shell with a piece of filter material mounted on the open front, rather than making the entire mask out of the typical "melt blown" filter material that "is so light and fragile it requires two other layers to protect it," says BioAid founder Marcus Hays. "That ends up dictating the assembly" and leads to the common monolithic N95 design that is hard to clean. Instead of using melt blown material, BioAid says it has developed a way to extrude sheets of commonly available polyethylene, like plastic grocery bags, to create a better filter. "The world is chasing melt blown, but (our) material can be decontaminated with a liquid disinfect, soap and water, or a bleach and water solution using CDC guidelines," says Hays.

BioAid says their extruded LDPE plastic results in a complex matrix of fibers for a hydrophobic, washable filtration medium.

Rather than deriving filtration efficiency from a random fiber structure and innate electrostatic charge that N95 melt blown material possesses, Hays says its filter relies on layers of opposed fiber grids and the fact that it's hydrophobic, rejecting moisture and being washable as a result. BioAID says they have tested it to be reusable 90 times, but is only seeking approval for a conservative 30 reuses to allow for some incorrect handling by wearers. The mask has been submitted to an independent lab for verification that it meets the OSHA 1910.134 standards that underlie an N95 designation.

The BioAid mask is thermoformed from a sheet of common packaging plastic much like what's used to create blister packs for pills or products on hooks at retail stores.

Hays' startup Orbis, based in Mill Valley, California, is developing in-wheel electric drive systems for automakers but temporarily pivoted to masks after an assessment of available materials such as polyethylene plastic sheets that are plentiful and familiar to many plastic thermoforming companies. The millions of blister packs, pill packs and water bottles they make are all close industrial cousins of the BioAid mask. "Normally it's not the most environmentally friendly way to go," Hays admitted. "But in this crisis, it's the smart thing to do."

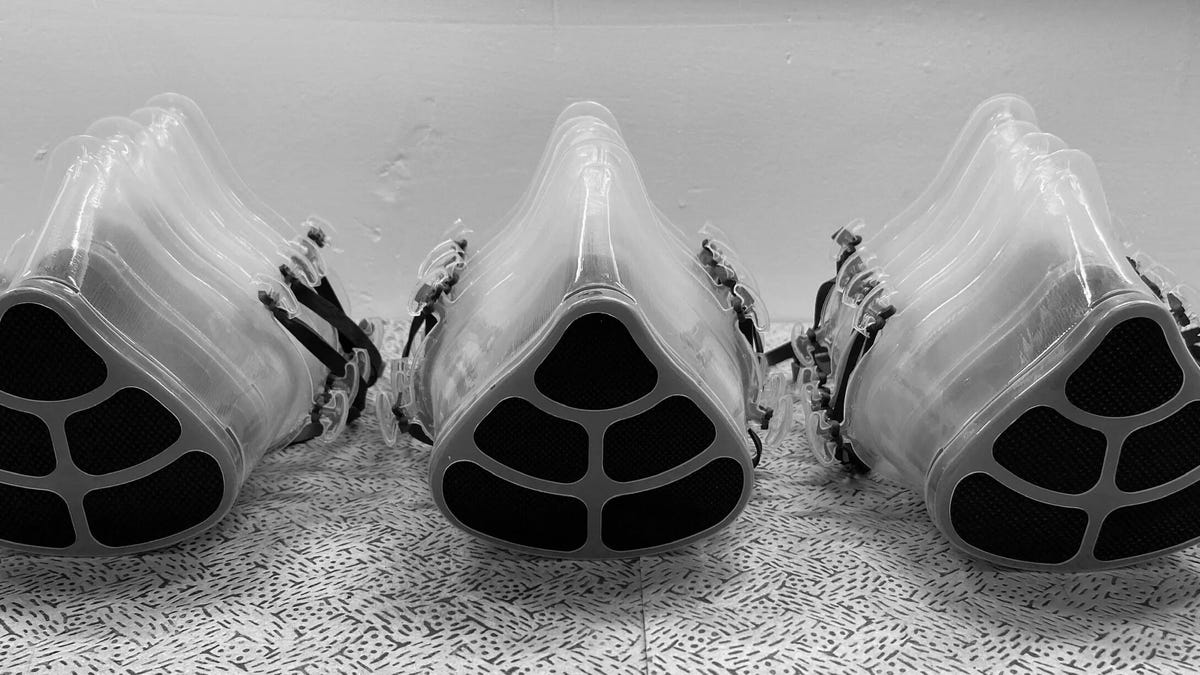

Since we shot the video above, a new BioAid mask design has emerged that uses larger front breathing holes in a rigid, reusable plastic facepiece holding a triangular swatch of filter material. "Important is the very small area of filter compared to a conventional N95," Hays says, allowing their design to conserve filter material and have discrete, cleanable parts. Verification that the breathing holes allow sufficient airflow will also determined by the OSHA 1910.134 certification.

The latest design of the BioAid facepiece uses a larger piece of filter material, but still less than the typical N95 respirator that is composed almost entirely of filtration material.

BioAid's original plan was to provides tools, dies, and manufacturing instructions under license to interested plastic thermoforming companies who would be mask OEMs. Now BioAid has decided to become the manufacturer via contract factories to maintain "chain of custody" over quality control. "The health community has been burned by too many flim flam artists," says Hays. As part of this approach, the company will also approach a channel partner to get their masks into retail once certified.

The Air Techniques International Protective Mask Leakage Tester that Orbis used to test sealing of BioAid mask as part of its intended N95 certification.

The CDC still recommends cloth face coverings rather than N95 level masks for the average person, though some of that advice has been driven by a shortage of N95 PPE. BioAid is just one of many efforts to solve the mask shortage problem, the sum of which constitute an ad hoc Manhattan Project that may change respiratory protection for the better. Given the recent arc of COVID-19 cases, that can't come too soon.