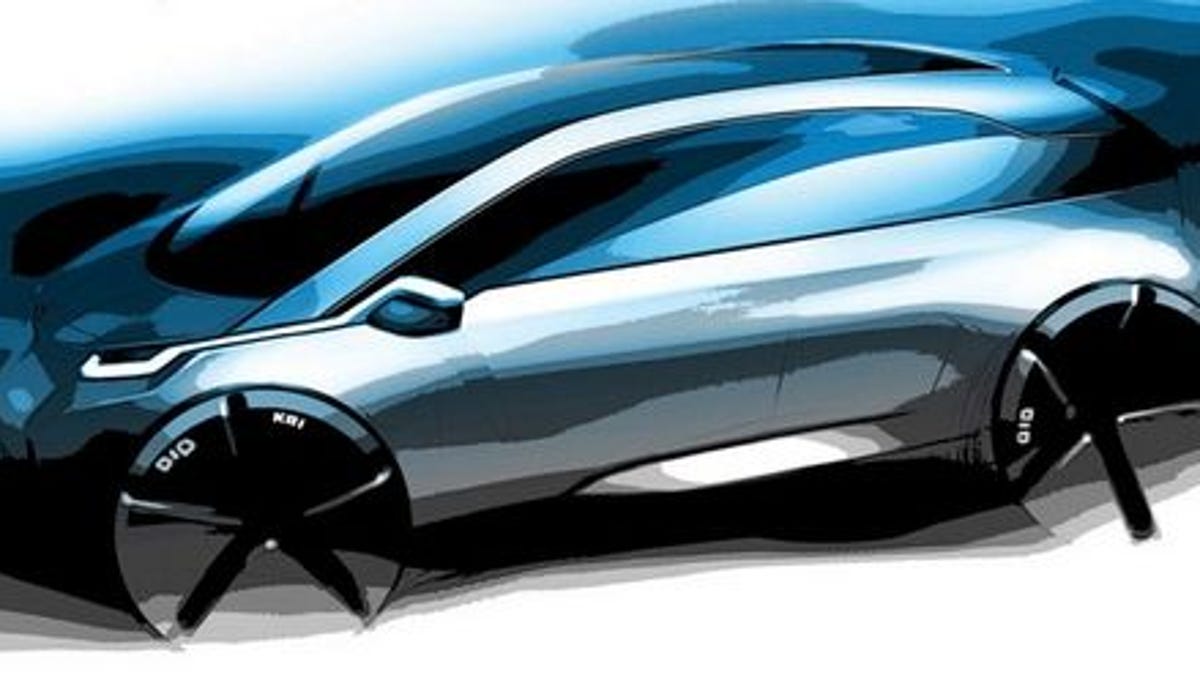

An e-mission statement

Automotive News reports on BMW's Megacity EV project.

When BMW brings out the Megacity electric vehicle in 2013, it will launch more than a small city car.

The Megacity EV will be no less than BMW's first stab at an environmentally benign car for the 21st century. It is the result of BMW's project i, a six-year rethinking of all aspects of the automobile.

BMW re-examined vehicle structure, materials, manufacturing and recyclability. "The overall project goal," says a company white paper, "is maximum sustainability."

BMW development chief Klaus Draeger said the scope of the project has been challenging.

"This is not like a normal car project," he said in an interview. "Every day you experience something new. But we want to be on the markets by 2013 in significant volumes."

Christoph Stuermer, an analyst at IHS Automotive in Frankfurt, said project i was a "wild think tank where people were absolutely free to question everything," but it is vital for BMW to spread its innovations throughout its lineup. Otherwise, BMW will be hard-pressed to continue to sell larger cars with premium pricing in a "greener, urbanized future," he said.

Key components of BMW's new model are:

-- Vehicle structure: Unlike most other small cars, the Megacity will not be a unibody vehicle. Instead, its structure will resemble that of a body-on-frame vehicle. BMW describes the design as "two horizontally separated independent modules."

The lower half is the "drive" module--an aluminum chassis that melds the battery, electric drive system and crash structure. A high-strength, lightweight, carbon fiber passenger compartment is attached on top. The key benefit is weight reduction, a prime consideration in reducing the weight and cost of the battery, while providing sufficient range, Draeger said.

-- Materials and manufacturing: Draeger said BMW will push suppliers for 100 percent recyclability of parts. Innovative use of weight-saving carbon fiber is a key to making the design work. BMW has partnered with SGL Automotive Carbon Fibers to build a carbon-fiber plant in Moses Lake, Wash.

He added that carbon fiber-reinforced plastic parts will be impregnated with color, removing the need for a paint shop. That will reduce energy use and emissions.

BMW will go to great lengths to reduce the cost of carbon fiber. BMW's process involves reuse of scrap, enabled by a new technique of turning carbon strands into sheets of fiber, Stuermer said. BMW will use a new "quasi-stamping process" to make smaller carbon-fiber-reinforced plastic parts than automakers normally use, saving cost and time.

-- Recycling: BMW will design the vehicle for recycling, Draeger said. But, he said, with the Megacity's design, its life cycle might be extended beyond current expectations.

"We could reskin it," he said. "We could recycle the body-in-white [exterior shell], although we are still working on that."

-- Consumer financing: BMW AG CEO Norbert Reithofer has said the company's initial EVs will be expensive and will probably lose money. That may spur the company to come up with extended leasing, perhaps with mandatory vehicle recycling, Stuermer said

Otherwise, the cost of the car would be a barrier, he said: "The consumer is looking at a small car with unproven technology that's likely to carry a very large price ticket. If you want to get into everyone's garage, you need to reduce the risk of ownership."

(Source: Automotive News)