3D printing gone wrong (pictures)

3D printing is opening up a brave new world of home manufacturing and cheap, accessible goods. But it's a relatively new pursuit, and sometimes it can go very wrong.

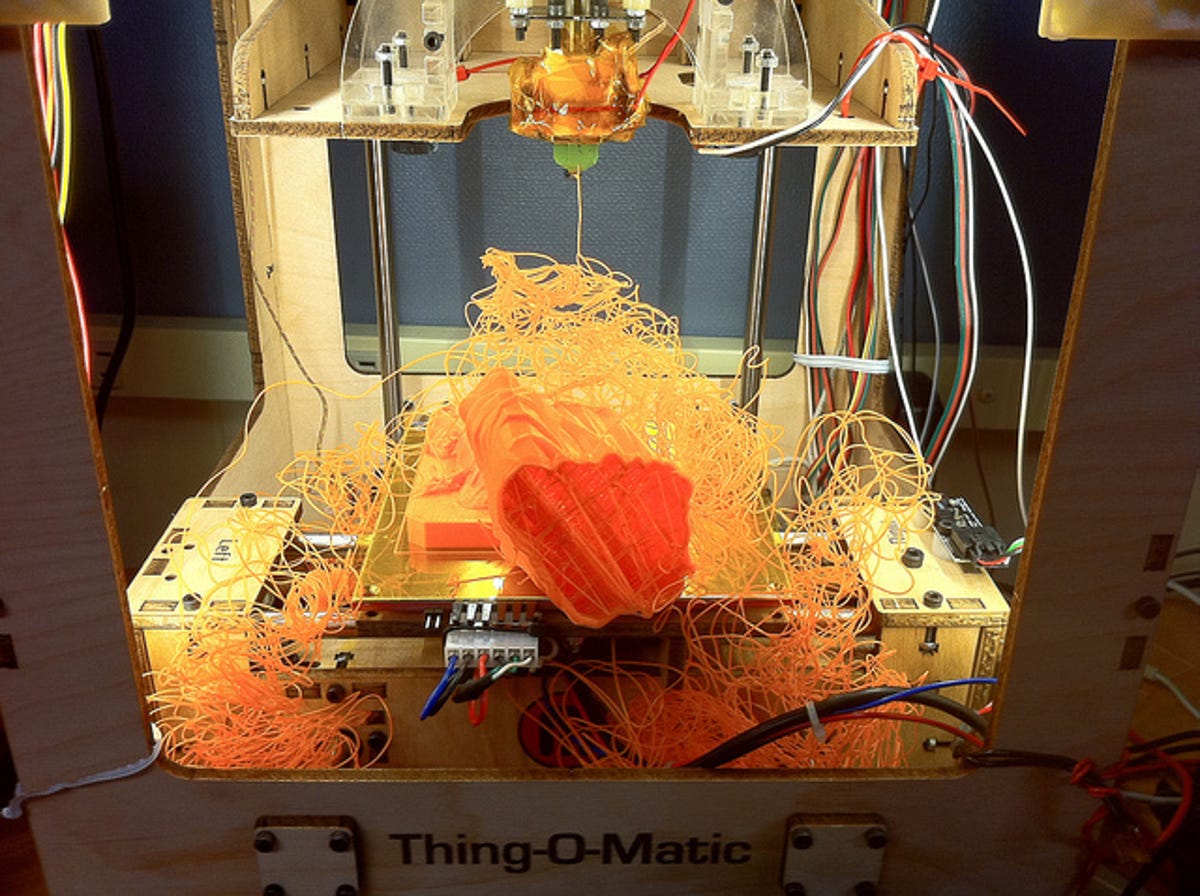

Lesson learned

The Art of 3D Print Failure Flickr group, inspired by a 2011 blog post that documents RepRap's own 3D-printing missteps, is entertaining to browse, but also extraordinarily useful. It highlights where and why 3D printing goes wrong so others dabbling in the technology can avoid the same mistakes.

"Untested settings and huge overnight unattended printing is rarely a good idea," Tony Buser notes of this tangle.

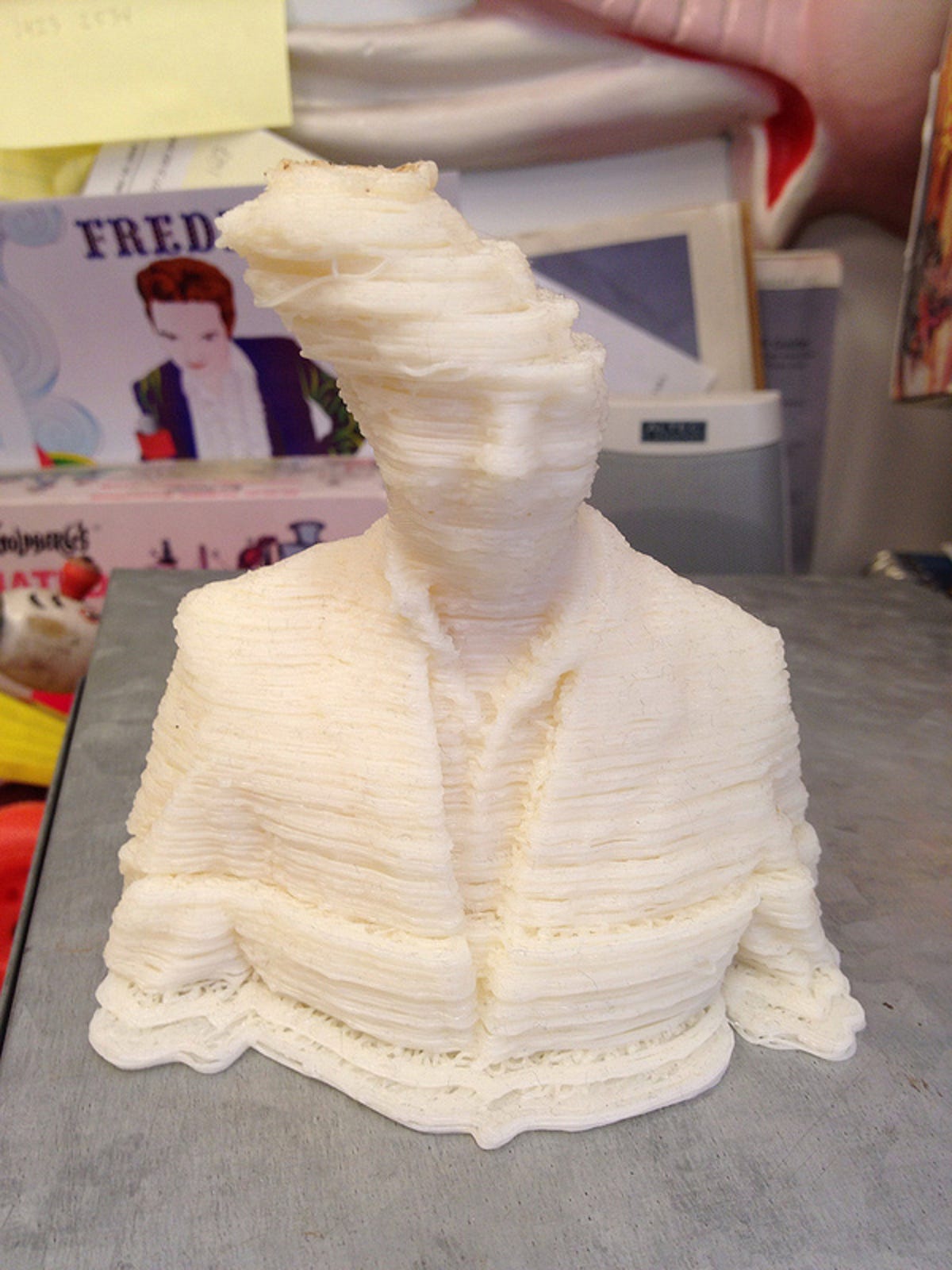

Strangely shaped skull

A lot can go wrong with 3D printing, a rapidly maturing technology that many people are just now learning how to use. Here, someone's head is looking a bit lopsided.

"It may sound odd, but it's really essential that you fail when doing 3D printing," says RepRap, whose own blog post about 3D printing inspired the Art of 3D Print Failure Flickr group. "It tells you so much about your machine, the boundaries you can operate in, and how good or bad things can be. If all you do is print with safe settings or never play with the electronics or firmware, then you are missing so much of this wonderful project."