What's so great about direct injection? (ABCs of Car Tech)

What is gasoline direct injection and how is it different from traditional methods of getting fuel into your car's engine?

You may have read or heard one of your favorite Car Tech editors talking about gasoline direct injection and how it's one of the "big technologies" that's helping to keep the almost 200 year-old internal combustion engine alive well into the 21st century. In this week's issue of the ABCs of Car Tech, I'm going to explain just what the heck gasoline direct injection is and why you should care if it's in your next car's engine or not.

How did fuel injection work before direct injection?

The modern gasoline internal combustion engine (ICE) needs three things to spin its crankshaft: oxygenated air, fuel, and a spark to make the air and fuel explode. The air is drawn through the intake where it's measured by the car's Mass Air Flow (MAF) sensor before passing to the intake manifold where the single intake path is split into four to eight intake runners, each of which leads into one of your vehicle's cylindrical combustion chambers. Somewhere along the line, the intake charge is mixed with fuel before the spark plug makes it all go boom inside the combustion chamber. This is all ICE 101 for most of you, I'm sure.

Back in the ancient days of engine technology, the carburetors and single-point fuel injection systems did their relatively imprecise air and fuel mixing in or even before the intake manifold, adding about the right amount of fuel for entire bank of cylinders. For the most part, each combustion chamber got the what it needed. However, depending on the design of the intake manifold, this approximation could result in the cylinders closest to the carb or fuel injector getting a bit too much fuel (running rich) while the cylinders farthest away got a bit too little (running lean). A skilled carburetor tuner (or smart engine computer) could keep things from getting out of control, but even the best tune was limited by the design of the intake manifold.

The vast majority of modern cars use a multi-point fuel injection (MPFI) setup (also known as port injection). Here's how it works: rather than using one injector that sprays about the right amount of fuel, each of the individual intake runners has its own injector (or injectors) that adds a squirt of aerosolized fuel to the intake air from a pressurized injector. The air and fuel mixture is drawn into the open port and into the combustion chamber by the retreating piston. The intake valve then slams shut, and the explosive combustion happens in the now sealed cylinder.

For the most part, MPFI is just fine and dandy. It's certainly much more efficient than the older carburated and SPFI systems thanks to its capability to adjust the amount of fuel added to the intake for each individual cylinder, equalizing the formerly lean and rich cylinders at the extreme ends of the manifold, improving power generation, and reducing wasted fuel. So, why fix what's effectively not broken?

How does direct injection improve performance?

You may have noticed that during the jumps from carburetion to SPFI to MPFI, the point at which fuel is added to the intake charge has moved from before the throttle to the intake manifold and onward to the individual intake runners -- closer and closer to the combustion chamber. Direct injection takes this evolution to the next level by placing the injector inside the combustion chamber. By moving the injector into the combustion chamber, gasoline direct injection (GDI) gains a few advantages over the previously discussed systems.

By putting the injector inside the cylinder, the engine's computer gains even more precision control over the amount of fuel during the intake stroke, further optimizing the air/fuel mixture to create a clean burning explosion with very little wasted fuel and increased power delivery.

A GDI system also has more flexibility regarding when in the combustion cycle the fuel is added. MPFI systems can only add fuel during the intake stroke of the piston, when the intake valve is open. GDI can add fuel whenever it needs to. For example, the some GDI engines can adjust the timing so that a smaller amount of fuel is injected during the compression stroke, creating a much smaller, controlled explosion in the cylinder. This so-called ultra lean burn mode sacrifices a bit of outright power, but greatly reduces the amount of fuel used during times when the vehicle requires very little grunt (idling, coasting, decelerating, etc.).

GDI engines also react more quickly to these changes in timing and amount of fuel addition, increasing driveability. Additionally, the vehicle is able to more quickly adjust based on inputs from sensors located downstream from the combustion chamber, keeping the dirty emissions blowing out of the tail pipe in check.

Some automakers have even experimented with using GDI to fire an additional burst of fuel into the cylinder to create secondary explosion during the combustion cycle, resulting in potentially even more power and efficiency.

Here's a fun fact: direct injection technology is not really as new as you may think. The technology has been around since the 1920s for gasoline engines and is actually already in use in most diesel engines.

Are there any potential drawbacks to GDI?

You may be asking, "If GDI is so great, why isn't it in every new car?"

Part of the reason is that manufacturing a direct-injected engine is more expensive due to component complexity, which means that the car the engine eventually powers would also be more expensive to buy. For example, the injectors on a GDI engine must be more rugged than port injectors in order to withstand the heat and pressure of hundreds (or even thousands) of tiny explosions per minute. Additionally, because a GDI system needs to be able to inject fuel into a pressurized combustion chamber, the fuel lines supplying the gasoline need to be even higher in compression. GDI fuel systems can run at many thousand psi versus the 40 to 60 psi of port injection systems.

The price of these components is dropping, but generally and for now port injection is cheaper and "good enough" for most economy cars.

Additionally, some owners and maintainers of GDI engines (particularly higher-performance, turbocharged models) have reported that direct-injection systems see increased carbon buildup in backsides of their intake valves, resulting in reduced airflow and performance over time. A quick Google search yields page after page of anecdotal reports of this issue. The buildup occurs because in most cars intake air is, frankly, kind of dirty -- even with air filters in place, modern exhaust gas recirculation systems and crankcase vent systems can add quite a bit of muck to the intake charge -- and without port injectors spraying gasoline (and the detergents that it contains) onto the valves, things can get pretty filthy over the course of many thousand miles.

Direct injection works well with other engine technologies

Automakers are finding all sorts of new ways to further refine the internal combustion engine with the aid of direct injection technology. For example, some automakers (including Ford, Audi, and BMW) are using GDI in combination with turbocharging to create low-displacement engines that get small engine efficiency with big engine power.

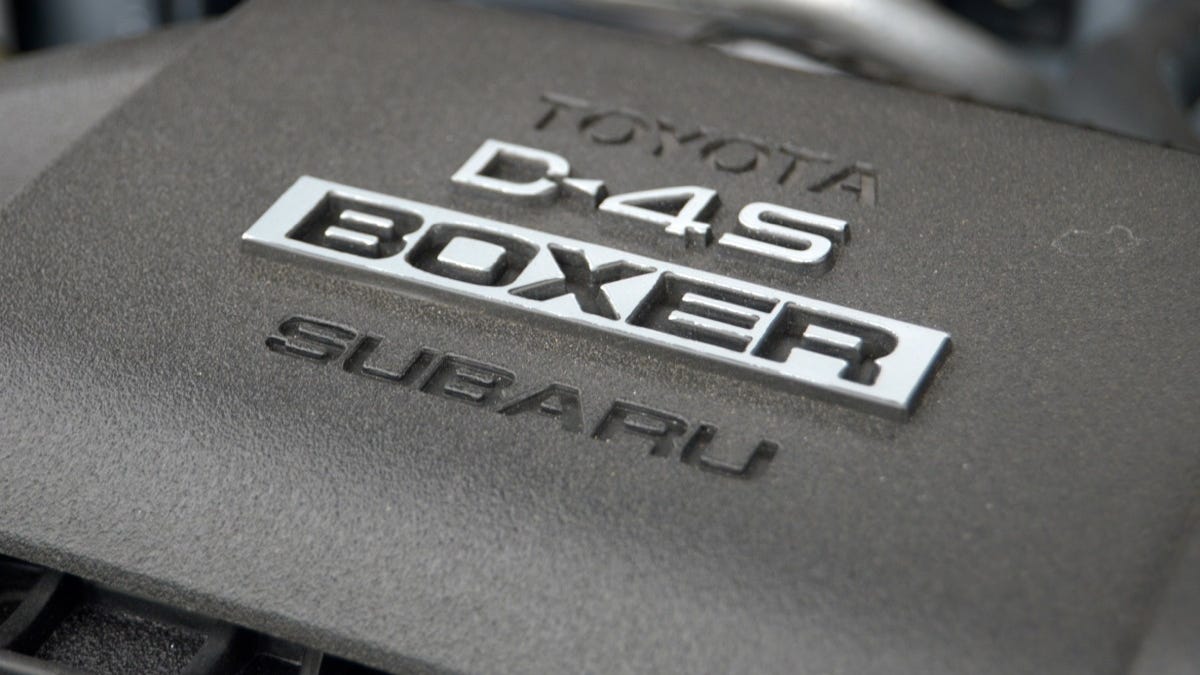

Toyota has offered its D-4S fuel injection system for a number of years with certain models of its 3.5-liter V-6 engine. The D-4S uses a combination of both direct and port injection to blend the best traits of both systems. As it's explained in this article from Wards Auto, the port injection system handles clean startup, the direct injection handles full load acceleration, and the two systems work in tandem to balance everything in between. This D4-S system is also used on the 2.0-liter boxer four-cylinder that powers the Scion FR-S and Subaru BRZ.