Power Felt could one day run iPod from body heat

Wake Forest researchers have developed a fabric of carbon nanotubes that potentially could generate power from a hot roof or be charged with body heat and used to power a phone.

Materials scientists have spun together carbon nanotubes into a fabric that promises a versatile and inexpensive way to transform heat into usable electricity.

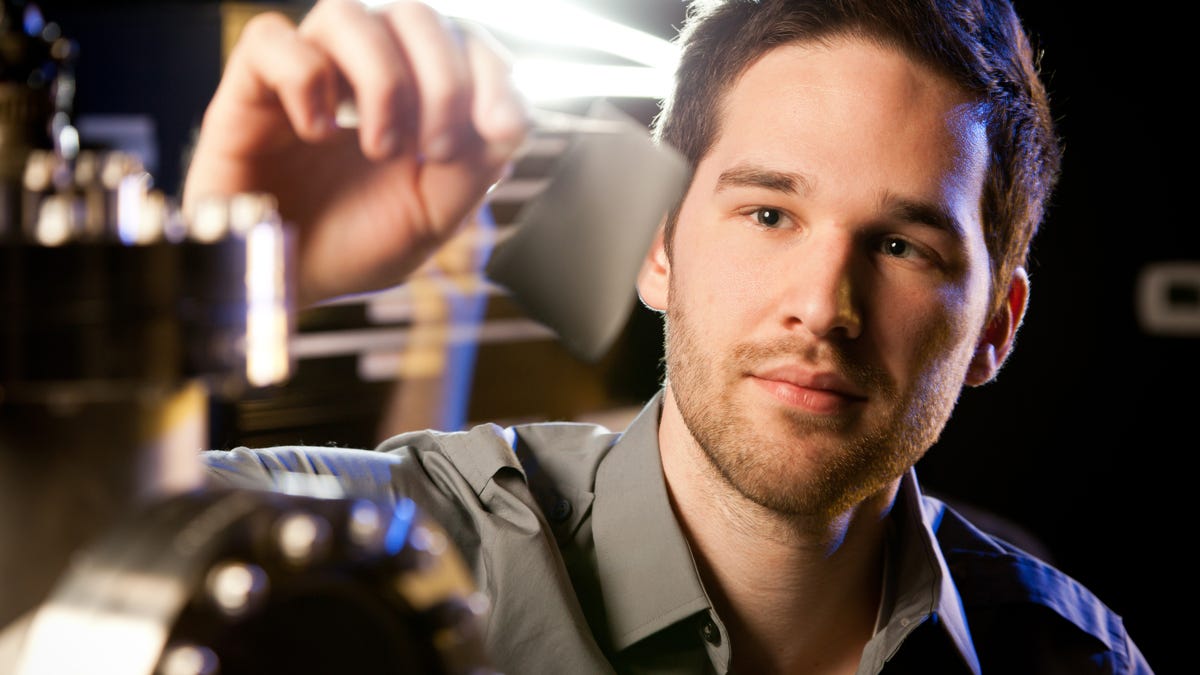

Researchers at Wake Forest's Center for Nanotechnology and Molecular Materials announced yesterday the creation of a thermoelectric device they say could open up new energy-harvesting applications.

The university is seeking to find investors to commercialize the technology, called Power Felt. If successfully developed further, it has the potential to use body heat from clothing to power an iPod or cell phone or power medical monitoring equipment from a wound wrap. Its makers also hope Power Felt can make electricity by being wrapped around hot water pipes or layered under roof tiles.

"Imagine it in an emergency kit, wrapped around a flashlight, powering a weather radio, charging a prepaid cell phone," David Carroll, director of the Center for Nanotechnology and Molecular Materials said in a statement. "Literally, just by sitting on your phone, Power Felt could provide relief during power outages or accidents."

Thermoelectric materials are already used in portable coolers or car seats, where a flow of electricity will remove heat from a surface and provide cooling. A number of researchers are trying to tap thermoelectric materials for generating electricity from heat, but the cost and efficiency is a barrier to broader use.

Though there has been research into making thermoelectric devices with carbon nanotubes, such devices have traditionally been made from bismuth telluride. The group at Wake Forest designed a flexible material from fibers made of carbon nanotubes, tiny cylinder-shaped molecules of interconnected carbon atoms.

The fabric is constructed with layers of plastic fiber, with each layer increasing the power output, according to the group's paper published in Nano Letters. One important advantage is that carbon nanotubes can be much less expensive. If made at large scale, a Power Felt charger cover for a cell phone could one day add only a dollar to the consumer cost of the cover, according to Wake Forest.

"Since these fabrics have the potential to be cheaper, lighter, and more easily processed than the commonly used thermoelectric bismuth telluride, the overall performance of the fabric shows promise as a realistic alternative in a number of applications such as portable lightweight electronics," the researchers said in the paper.

The group at Wake Forest intends to make thermoelectric devices with multiwalled carbon nanotubes, where there are multiple layers of cylinders wrapped around each other. The focus of their work now is to add more nanotubes to boost the power output and make them thinner.