Oily Bits: The Intake System

To allow an engine to function properly, and for it to be controlled, it needs an intake system. Intake systems for petrol engines, which should be designed to deliver a balanced flow of air to each cylinder in the engine, consist of several parts: the intake manifold, a fuel delivery system, a throttle assembly and an air filter.

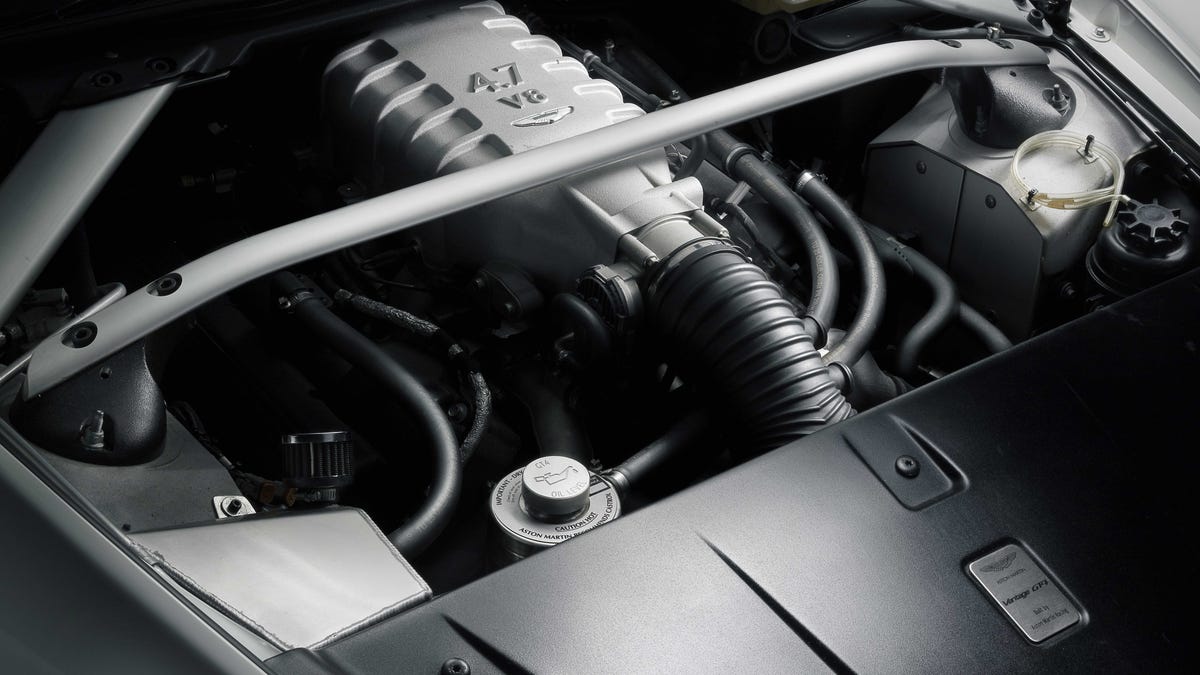

The intake manifold bolts to the cylinder head and channels fresh air and fuel to the engine's intake ports. Intake manifolds usually feature a series of tubes, called runners, which travel from the intake ports to a larger tube or box called a plenum. This helps balance the flow of air.

Intake manifolds sometimes contain components that supply fuel to the engine, like fuel injectors, as well as sensors that are used to monitor how the engine is running and how much fuel it needs.

Controlling the flow of air in to the engine, and consequently its speed, is the throttle assembly. Effectively a valve, it's controlled by the position of the accelerator pedal. Change the position of the throttle and you alter the amount of air getting in to the engine, which alters the amount of fuel burned and the power delivered.

Older cars tend to have their throttle integrated into components called carburettors, which also deliver fuel. Most modern engines have one throttle, usually part of a throttle body which features various sensors, but high-performance engines can have one throttle assembly per cylinder for improved air flow and better response.

Diesel engines don't have a conventional throttle system, because the power output of a diesel is controlled by adjusting the amount of fuel supplied to the engine. Air is drawn in to the intake system through an air filter. This removes much of the dirt and debris from the incoming air, which reduces wear and tear on the engine's internal components.

The air filter is usually housed in a specially designed housing, which serves to reduce the engine's intake noise. More often than not the filter housing also takes advantage of the high-speed air hitting the front of the car, with the filter taking in air from that area near the front of the engine bay, which helps to force air in to the engine.

So, in a modern car air travels through the air filter, past the throttle assembly and in to the intake manifold. In the intake manifold it may be mixed with fuel, at which point it's drawn in to the engine through its intake ports. Some modern cars inject the fuel directly into the combustion chamber, so the intake system just exists to provide a controlled flow of air to each cylinder in these instances.

In older cars the process is much the same, with the air flowing through an air filter but then directly into the car's carburettors. These control the flow of air in to the engine, as well as mixing it with fuel. The fuel air mixture then travels down the intake manifold, in to the engine.

Individual injectors or carburettors can be used to feed multiple cylinders but obviously they have to be larger to accommodate the increased demand upon them.

Performance intake systems aim to primarily improve air flow, using better manifolds, freer-flowing air filter assemblies and bigger throttle bodies. More air in the engine means more fuel can potentially be burned, generating more power.