A123 Systems stung by faulty batteries

Battery maker A123 Systems will need to replace batteries to the Fisker Karma and other vehicles following the discovery of a defect at its Livonia, Mich., battery plant.

A123 Systems will need to replace defective batteries made at its Livonia, Mich., plant, costing the company $55 million.

The company announced today it has isolated the problem and will begin sending replacements battery packs and modules this week. One of the cars affected is the Fisker Karma, which Consumer Reports testers were unable to start during a review earlier month.

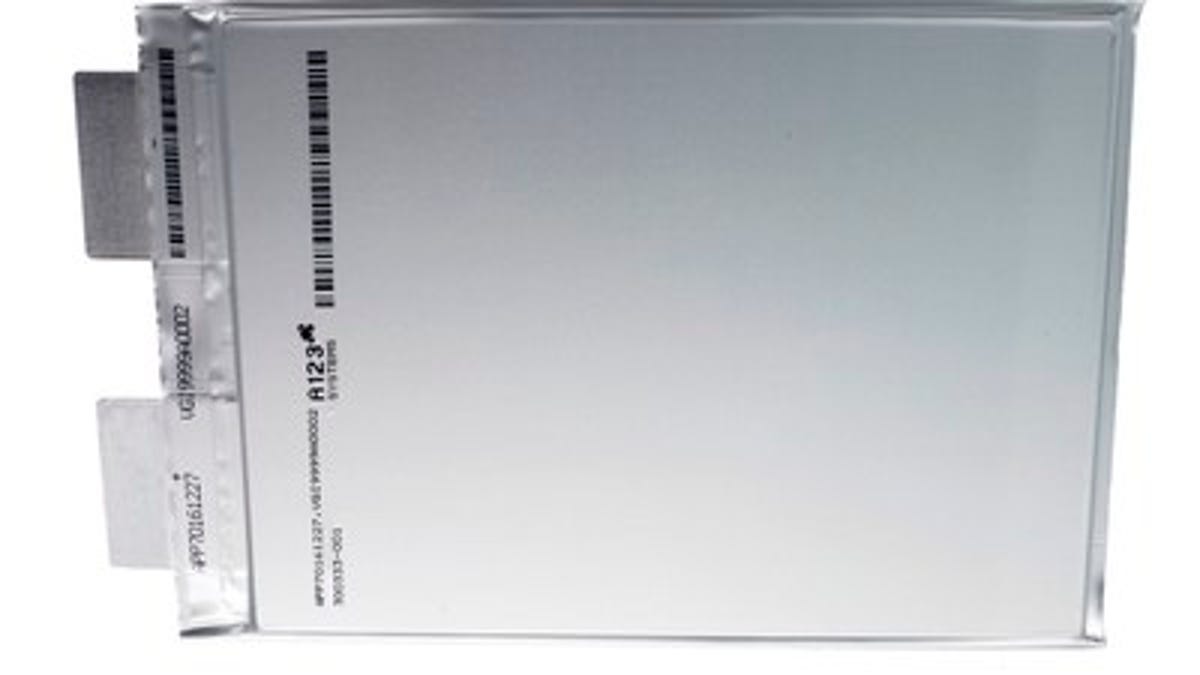

A defect in A123 Systems' prismatic lithium ion cells can cause batteries to short out and prematurely fail. The company said it is confident that it has isolated the problem to a single automated welding machine at its Michigan plant, CEO David Vieau said during a conference call today.

An incorrect calibration of one welding machine caused a misalignment of certain components in a battery cell. That misalignment can cause a break in the electrical insulation and a potential short, Vieau explained.

There are five auto companies affected by the defect, including Fisker which purchases large battery packs for its Karma plug-in hybrid luxury car. In the case of the Karma, the defect can prevent the car from starting after the driver parks the car but not a sudden loss of power, Vieau said.

"We believe the defect does not create a safety issue," Vieau said. "This situation is ultimately a packaging issue for which we have identified the root cause."

Prismatic cells made in another location and cylindrical cells made at A123 Systems' manufacturing plant in China are not affected.

Vieau said the defect problem stemmed from the company's initial ramp up at the Michigan plant. A123 Systems received $249 million grant from the federal government to build the plant, part of a strategy to bring battery manufacturing to the U.S.

The defect is another bit of bad news for A123 Systems, which has seen its stock languish amid concerns over demand for its batteries, particularly in transportation.

It is supplying batteries for the Fisker Karma, but Fisker Automotive had delays in releasing the plug-in hybrid and scaled back sales projections. Earlier this month, it reported a net loss of $85 million in the fourth quarter on revenue of $40.4 million.

Vieau said that the company has sufficient liquidity to deal with the situation but that it will affect funding strategy.

"This is a new industry with new technology that's in the process of a learning curve," he said. "It's not anticipated but not totally unexpected that some problems will occur."